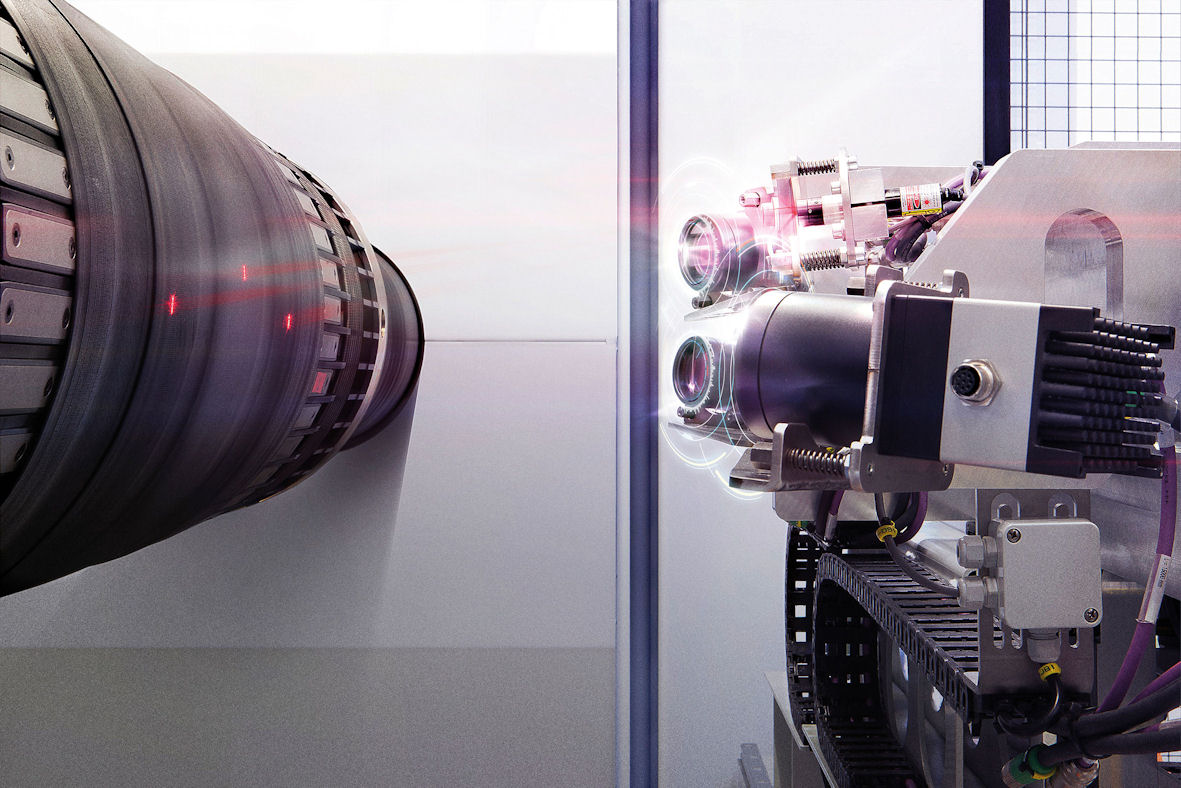

VMI wins Pirelli Supplier Award 2018

During a ceremony held at Pirelli’s headquarters in Milan, Italy recentlym VMI received the Supplier Award for high quality and support. Chief purchasing officer Matteo Battaini handed over the Award to Harm Voortman, CEO of VMI Group: