Wang Lin becomes vice chairman of Linglong Tire

Wang Lin was recently elected as vice chairman of Linglong Tire. According to the Linglong’s announcement of the news, Wang Lin’s appointment is intented to “meet Linglong Tire’s future development needs, further improve the corporate governance structure, and improve the operating level and work efficiency of the company’s board of directors.” His responsibilities are to “assist the chairman in carrying out his work.”

Linglong Tire

Linglong Tire Linglong

Linglong Oohsnap; Pixabay

Oohsnap; Pixabay

Scott Graham; Unsplash

Scott Graham; Unsplash

Fin

Fin Linglong

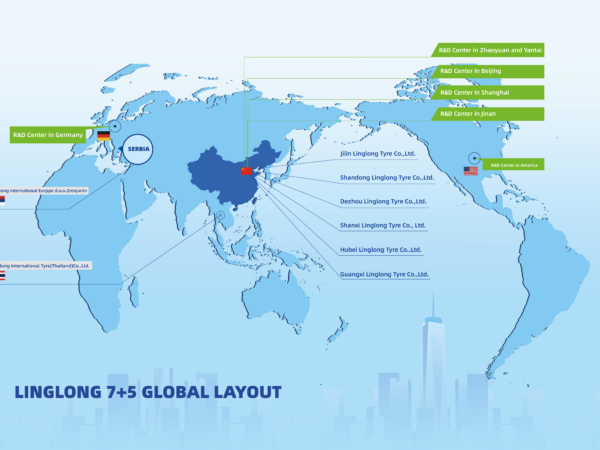

Linglong Linglong

Linglong Prinx Chengshan

Prinx Chengshan

Linglong

Linglong