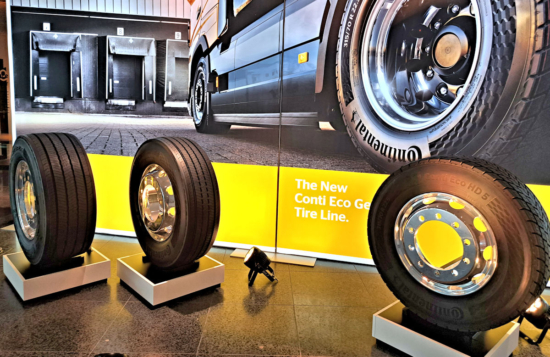

Sustainably affordable – Conti Eco 5

Conti Eco HS 5 (315/385) & Conti Eco HD 5 (Photo: Stephen Goodchild / Tyre Industry Publications Ltd)

Conti Eco HS 5 (315/385) & Conti Eco HD 5 (Photo: Stephen Goodchild / Tyre Industry Publications Ltd)

During the official launch of its fifth-generation Conti Eco truck tyre range, the team at Continental frequently touched on the subject of sustainability, addressing this as both as a desirable target for fleets and as a factor driving massive legislative change in Europe. Cost pressures were also high on the agenda. To accommodate the demands posed by both factors, Continental states its aim of finding the right balance, meeting cost targets in the most sustainable way.

Ferdinand Hoyos, head of the Replacement Tires EMEA business area, sees “absolutely tremendous” regulatory demands upon Continental’s customers in European countries, including the UK. Although lawmakers mean well, the result is that transport fleet operators must invest “a lot of work” into compliance with current and upcoming CO2 emission and sustainability regulations.

“Sustainability is something which becomes the new normal,” elaborates Hoyos. “Many view it as the license to operate. If you’re not fulfilling sustainability targets, if you’re not supporting your customers to meet those sustainability targets, then you are out.”

Those wishing to remain in the game, then, must juggle sustainability along with macroeconomic volatility, inflation, labour shortages and other cost factors. Arguably a tall order, but for Hoyos and Continental this represents an “opportunity to engage.” The business area head emphasises that Continental has chosen to become a “frontrunner” in the area of sustainable performance to provide the “best possible solutions for our customers in order to make their lives better.”

Introducing Generation 5

One such solution is the fifth-generation Conti Eco tyre line, which by replacing both the Conti EcoPlus Gen 3+ and Conti EcoRegional Gen3+, caters to both long haul and regional applications.

Continental says it was able to replace two tyre lines with a single product by optimising two qualities of significance to the sustainability and cost issues we mentioned earlier. Rolling resistance has been reduced while mileage potential is up.

Rolling resistance and mileage have long been conflicting goals when designing tyres. Hinnerk Kaiser, who is responsible for the development of truck and bus tyres at Continental, tells us that his team began its efforts to optimise rolling resistance and mileage by focusing upon something that accounts for up to half of a tyre’s overall rolling resistance, the tread.

“Our solution was a fusion of compound and geometry,” elaborates Kaiser. “For the compound, we opted for a new blend of natural rubber and butadiene rubber, enabling the compound to excel in resistance and wear simultaneously. Then we selected a shape that exerts less pressure in the shoulder area, reducing hysteresis. This aids in enhancing the rolling resistance performance of the entire tyre package.”

According to Continental, the tread’s compounds and two-layer ‘cap-base’ construction enable high mileage and offer robustness while also optimising rolling resistance. The tread design comprises a base compound optimised for rolling resistance, complemented by a cap compound focusing on mileage performance.

Hinnerk Kaiser, head of truck & busy tyre development (Photo: Stephen Goodchild / Tyre Industry Publications Ltd)

Optimised casing

The development team used a number of “mileage neutral” measures to improve rolling resistance across all components. Hinnerk Kaiser points out that the casing, for example, “confers the advantage of not compromising any other performance criteria.” By optimising the casing through improvements to the materials within the sidewall, squeegee and bead elements as well as the construction of these components, Continental says it was able to enhance rolling resistance performance without sacrificing any other tyre characteristics.

To ensure the Conti Eco Gen 5 range’s suitability for both regional and long-haul scenarios, Continental used a four-layer belt in the casing construction. Kaiser points out the “novel circumferential layout” of the second layer, which is aligned longitudinally at 0° to promote even wear and enhance stiffness at the bead edge, characteristics that prolong tyre service life.

“What’s more, the beauty of this casing optimisation is that it also benefits retreaded tyres later on. Even in the tyre’s second or third life, the effect of improved rolling resistance of our new Conti Eco Gen 5 persists,” adds Kaiser.

Rolling resistance, mileage improvements

At launch the fifth-generation Conti Eco range consists of the Conti Eco HS 5 steer tyre and Conti Eco HD 5 drive tyre. Trailer tyres will join the range in 2026, with the EcoPlus HT3+ satisfying demand until then. Other EcoPlus and EcoRegional products remain in production as well to accommodate original equipment supply arrangements, but Continental will phase out these lines once OEMs adopt the latest generation of tyres.

The Conti Eco is initially available in the following sizes:

- 315/70 R 22.5 Conti Eco HS 5

- 315/80 R 22.5 Conti Eco HS 5

- 385/55 R 22.5 Conti Eco HS 5

- 385/65 R 22.5 Conti Eco HS 5

- 315/70 R 22.5 Conti Eco HD 5

- 315/80 R 22.5 Conti Eco HD 5

What is the end result of Continental’s efforts? Hinnerk Kaiser tells us that the HS 5 offers a 12 per cent improvement in both rolling resistance and mileage over its two predecessor tyres, while the HD 5 delivers a ten per cent improvement in rolling resistance and two per cent improvement in mileage. EU label results for rolling resistance, wet grip and noise are B/B/A and B/C/A respectively. “The Gen-5 tyres provide the same great retreadability that our customers are used to from our Hybrid product line, and they are, in their segment, the first EU taxonomy compliant tyres.”

ContiConnect solutions

As mentioned, Ferdinand Hoyos promises the “best possible solutions” for Continental customers, and these solutions go beyond the tyres themselves. Under a concept known as LODC – lowest operating driving cost – Continental strives to reduce fuel/energy consumption, avoid breakdowns, maximise tyre mileage, ensure safety and compliance and ease operations by making its tyres more intelligent. It offers these solutions under the Conti360° banner.

Intelligent tyre monitoring solutions include the original, 2010-launched ContiConnect Pressure Check (originally known as ContiPressureCheck) which connects in-tyre sensors with a display in the driver’s cabin. Fleets wishing to manage their vehicles directly can choose between ContiConnect Yard or, if trucks don’t regularly return to a specific depot, ContiConnect Live, which utilises in-vehicle telematics to communicate data.

As part of the LODC concept, all new Continental truck tyres are equipped with sensors. Continental will introduce a third generation of its sensor by the end of 2024 or early 2025, and Clarisa Doval, who is head of digital solutions at Continental, shares that this sensor will expand the ContiConnect remit by measuring tread depth. This will help ContiConnect estimate mileage potential.

Online in minutes

But not all fleets run on 100 per cent Continental tyres, and not all brands of tyre come from the factory with built-in sensors. “We saw that equipping a really large fleet with our sensors is not always easy,” says Doval. “If a fleet has thousands of trucks, finding the right moment to mount tyres with internal sensors isn’t easy. It is a big endeavour.” A solution to this dilemma is the ContiConnect Valve Cap Sensor, which Continental announced at the end of 2023.

“It takes less than a minute to screw on the valve, which means an entire vehicle can be online in a matter of minutes using the Valve Cap Sensors,” comments Doval. Although the data this solution supplies isn’t as comprehensive as that delivered by the second-generation and upcoming third generation ContiConnect sensors, it represents a “pretty good entry level solution.”

The ContiConnect Valve Cap Sensor enables fleets to quickly equip their vehicles for monitoring (Photo: Continental)

A level beyond entry level actually exists, and costs nothing. Any fleet seeking basic monitoring capabilities without having to pony up for sophisticated solutions can turn to ContiConnect Lite. “We released this just a few months ago,” says Clarissa Doval. “This mobile phone app is easy to use and is free. Anyone who has sensors inside their tyres can download the app and immediately read tyre pressure and temperature.”

Tread depth and mileage measurement capabilities will join the ContiConnect portfolio very soon, and Doval believes this will be a “big differentiator.” But what does the future hold? The head of digital solutions tells us that ContiConnect will become more adroit at predicting tyre performance. “Continental has a large team of artificial intelligence engineers working on models, and these are very advanced. We will connect AI with vehicle inspection solutions that can be accessed via a mobile phone.”

Comments