7 years early – Nokian Tyres achieves 2030 CO2 goal

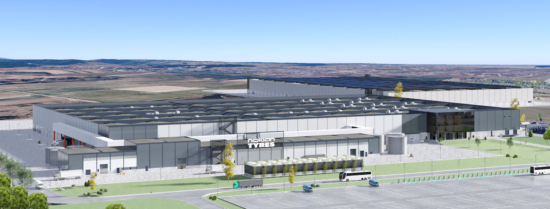

The new factory in Oradea, Romania is an “important step” to net zero (Image: Nokian Tyres)

The new factory in Oradea, Romania is an “important step” to net zero (Image: Nokian Tyres)

When it comes to climate targets, 2030 seems to be the golden year. But Nokian Tyres has jumped the gun in the best possible way, reaching one of its key emissions reduction targets seven years ahead of schedule.

One of the company’s science-based greenhouse gas targets was to cut CO2 emissions per production tonne at its tyre factories by 52 per cent (compared with 2015) before the end of 2030. It achieved this target in 2023, with factory emissions per production tonne the lowest in the tyre industry. But Nokian Tyres says it will continue its work to reduce these even more.

Under 200kg per tonne of tyres

In 2015 direct CO2 emissions from Nokian Tyres factories amounted to 723kg per tonne of tyres, therefore a 52 per cent reduction would be emissions of no more than 347kg per tonne of tyres. It came close in 2022, with direct CO2 emissions from its plants amounting to 420kg per tonne of tyres manufactured. This year, Nokian Tyres has more than halved its direct CO2 emissions, reporting that it is “already progressing rapidly toward a level of less than 200kg per tonne of tyres manufactured.”

This CO2 emission level was the lowest in the tyre industry: CDP Climate reports and tyre makers’ corporate sustainability reports indicate that the majority of tyre manufacturers operate between 700 and 1,100kg.

Urgent action needed

“Urgent actions are needed to tackle climate change, so even though Nokian Tyres’ factory greenhouse gas emissions are at an industry-leading level, we consider it important to cut the emissions to zero as soon as technically possible. In the best case, it leads to setting new sustainability benchmarks that can have a positive impact on how the whole industry operates,” says Teppo Huovila, vice president of quality, sustainability and supply operations business development at Nokian Tyres.

The road to net-zero greenhouse gas emissions

The target that Nokian Tyres achieved this year is one of the company’s four science-based greenhouse gas emissions reduction targets. Two of the targets are related to emissions from the supply chain, and one target is to reduce emissions during tyre use.

“Besides the emissions from tire manufacturing, the emissions during tyre use are something that Nokian Tyres’ own actions and choices can influence the most,” says Huovila. “The lower the rolling resistance of tyres, the less fuel or energy the vehicle consumes. Between 2013-2022, Nokian Tyres has reduced the rolling resistance of its tyres by 8.5 per cent on average. This equals to the exhaust fumes of 65,000 cars annually.”

CO2 emissions during tyre production mainly result from a factory’s energy mix, with emissions reduceable by purchasing energy from zero-CO2-emission sources. Energy use can also be lowered by improving energy efficiency, a factor that Nokian Tyres says it considers when procuring new machinery, updating factory lighting or when implementing heat recovery solutions.

Ambitious aims

Nokian Tyres is in the process of updating its science-based climate targets with even more ambitious aims. The company is committed to setting targets that result in net-zero greenhouse gas emissions by 2050 and views the new factory being built in Oradea, Romania as an ”important step on the journey.” This will be the first zero CO2 emission tyre factory in the world.

Comments