Virtual prototyping delivers numerous benefits to Vredestein Quatrac Pro EV

Apollo Tyres believes simulation has allowed it to “unlock new levels of year-round performance” (Image: Apollo Tyres)

Apollo Tyres believes simulation has allowed it to “unlock new levels of year-round performance” (Image: Apollo Tyres)

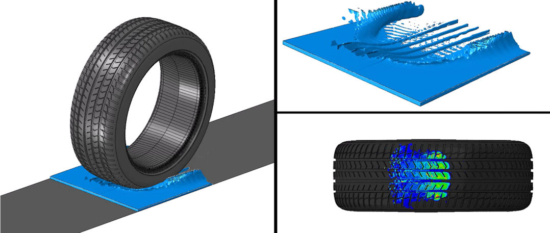

Apollo Tyres has shared details about the recently-launched Vredestein Quatrac Pro EV, Europe’s first dedicated all-season tyre for electric vehicles. Specifically, the manufacturer sheds light on tyre development using its state-of-the-art virtual prototyping and simulation platform and how this helped to “dramatically reduce time-to-market as well as the product’s environmental impact and development costs.”

Virtual prototyping ensured the development cycle for the Quatrac Pro EV was the fastest for any Vredestein tyre to date. Apollo Tyres utilised the in-house simulation and prototyping platform that its R&D team in Enschede, the Netherlands has enhanced over many years and credits this with improving the overall efficiency of design and testing processes and enabling the company to achieve “ambitious performance targets.”

As the tyre maker relates, a greatly increased use of computer simulation allowed it to apply a “rapid iterative design approach” when optimising critical performance characteristics, including rolling resistance, grip, comfort and road noise. For example, the R&D team used the simulation technology to optimise the construction of the tyre’s contour and tread to reduce rolling resistance and thereby increase driving range. “The result is a product that performs well year-round, across a wide range of road surfaces,” comments Apollo Tyres.

The technology also helped Apollo Tyres reduce the Quatrac Pro EV’s carbon emissions during development. As well as requiring fewer physical testing miles to evaluate the tyre ahead of launch, the increased use of computer simulation facilitated a substantial reduction in raw materials used for evaluating trial compounds and for the production of test tyres.

Benchmarked against its regular all-season tyres, Apollo Tyres reports that the Quatrac Pro EV has a 17 per cent lower environmental impact (measured as Global Warming Potential of CO2), contributing to a lower lifecycle carbon impact.

Efficiencies for competitive pricing

In addition to environmental benefits, Apollo Tyres claims virtual prototyping and simulation platform allowed it to access new R&D process efficiencies. “This helps the company maintain highly competitive pricing for end-users, despite the tyre setting new, premium-grade levels of performance and efficiency in the EV tyre category,” adds the tyre maker.

“The steady increase in the use of virtual prototyping in our product development has been a game-changer for our business, enabling us to meet and exceed performance criteria in a fast and reliable way,” explains Dr Udo Kuhlmann, group head R&D Europe at Apollo Tyres. “We’ve been investing in simulation software for over 25 years; our latest virtual prototyping environment is now key in helping us maintain a competitive edge.

“Real-world testing remains crucial – our tyres are often bought by driving enthusiasts and we must apply subjective as well as virtual assessment. We are now harnessing industry developments in high-performance computing and cloud-based simulation to further improve the platform,” concludes Kuhlmann.

New levels of year-round performance

Apollo Tyres believes simulation allows it to “unlock new levels of year-round performance.” As an example of this, Apollo points to the stiffer blocks and inter-connected ‘bridges’ on the tyre’s shoulders that, when combined with high silica content in the tread, deliver high levels of wet and dry braking – the latter reportedly four per cent better than the equivalent non-EV all-season Vredestein tyre. The Vredestein Quatrac Pro EV also carries the 3PMSF (Three Peak Mountain Snowflake) symbol on its sidewall to verify proficiency in winter conditions.

Furthermore, Apollo Tyres tells us that the Quatrac Pro EV offers a six per cent improvement in handling performance, five per cent less noise and a 15 per cent improvement in rolling resistance compared to its non-EV-focused sibling, thanks to a carefully optimised blend of fourth-generation polymers and ‘smart’ silica for the tread compound, rim cushion and casing.

“As Europe’s first dedicated all-season EV tyre, the Quatrac Pro EV has been designed to manage the unique characteristics of modern EVs, including dealing with elevated torque and higher vehicle weight, while delivering superior standards of handling, stability and driver engagement,” states Apollo Tyres. “It also offers significantly lower levels of rolling resistance and provides a quieter and more comfortable ride, tailored to the unique characteristics of an EV.”

Quatrac Pro EV is also the first all-season tyre ever to come with the HL mark, signifying ‘High Load’ readiness (255/40 R 20 being the first variant). This confirms the tyre is able to carry ten per cent more weight than a reinforced ‘Extra Load’ (XL) tyre at the same pressure.

Comments