Enter the Future: BKT to become an OTR one-stop shop

BKT shared its plans at the Enter the Future event. Participants included Chairman and MD Arvind Poddar (4th from left), Joint MD Rajiv Poddar (3rd from left), Dilip Vaidya (5th from left), CEO of BKT Europe Lucia Salmaso (Photo: Pneusnews.it / Ludovico Bencini)

BKT shared its plans at the Enter the Future event. Participants included Chairman and MD Arvind Poddar (4th from left), Joint MD Rajiv Poddar (3rd from left), Dilip Vaidya (5th from left), CEO of BKT Europe Lucia Salmaso (Photo: Pneusnews.it / Ludovico Bencini)

In February, BKT announced its aim of increasing production by around 67 per cent and achieving an annual turnover of US$2 billion in three years. The company’s Bhuj facility in western India is key to these plans and will soon manufacture numerous new products, including off-highway truck tyres, agro-forestry radials, tracks and an expanded mining tyre portfolio. BKT shares news of these and other plans.

The BKT of 2026 will be very different from today’s company. The foundations will still be the same but the product range much broader. The tyre maker’s flagship plant in Bhuj will almost double in size and employee headcount, with workers living in a factory village together with their families.

During an event held in mid-February, BKT presented its business plan 2026, a plan that as said above envisages doubling turnover to US$2 billion and annual production capacity to 600,000 metric tonnes. The name of the event was fitting: Enter the Future.

Announcing these goals, joint managing director Rajiv Poddar commented: “These are challenging targets but I am confident that we can achieve them. If I look at the initial plans for the Bhuj plant, I never thought we would reach the state we are in today, both financially and physically. Today this is not just a tyre factory, it is much more. It is a carbon black plant, an energy producer, but also a home for many people. Today we have the experience, the heart and the potential to get there, despite the challenges of a very aggressive market, global social political and economic uncertainties.”

Bhuj site to grow 25%

It goes without saying that a goal of doubling turnover in four years will entail major changes within the company. BKT is working to digitise processes, expand capacities, ranges and its customer base, and planning for the future in regards to its workforce.

But first things first. The initial step is purchasing the land around the Bhuj plant: The plant site covered 258 hectares in 2022 but is expected to grow to a total area of 323 hectares by the end of this year. BKT will build new factories for both tyre and carbon black production on the acquired land as well as housing and facilities for employees.

BKT representatives at the growing Bhuj site (Photo: Pneusnews.it / Ludovico Bencini)

In addition to the agricultural and mining tyres we are all familiar with, BKT will produce solid tyres, forestry tyres, off-highway truck tyres and tracks on this new land. Dilip Vaidya, senior president & director (technology) at BKT, presented these new products.

New products aplenty

The first to market will be industrial tyres, available from the second half of this year. “We will have a complete range for forklifts as well as for machines working in the mining sector. We will provide more information in due course, but for now I can say that the product will feature a ‘cushioning effect’ that reduces vibration, improves comfort and reduces damage to machinery, which in turn will increase the lifespan of the tyres themselves.”

The second item of news is forestry tyres. BKT already offers a range for harvesters and forestry applications with forwarders, but announced the impending arrival of a new range of agro-forestry radial tyres called Forestmax. These tyres for forestry tractors focus upon stability and minimising downtime with 8-ply casings and triple steel belts. The first dimensions will be available in the third quarter of 2023. Additional cross-ply forestry sizes will also arrive from Q3 2023.

We had a sneak preview of BKT’s tracks last year: “We showed the tracks at SIMA and EIMA, arousing great enthusiasm in the market and exceeding our wildest expectations. We are in a phase of continuous development: The next step is to work on tracks for combine harvesters. The first sizes available for testing will leave the factory in May 2023.”

Moving on to mining, and Vaidya announced three new Earthmax SR468 sizes, 40.00R57, 37.00 R57 and 46/90 R57. In addition, Earthmax SR53 is also coming in size L5 60/80 R57, a dimension suitable for the largest Caterpillar and Komatsu machines. “This is a category occupied only by premium tyre manufacturers and it represents a big step for our company. We will receive the moulds in May and by August be ready to begin sales. We are also working on a tyre wear management system specifically for mining; it will be the most efficient solution on the market.” Dilip Vaidya didn’t reveal specific details but did say the system “will report the condition of the tyre every 24 hours and the condition of the route every hour.”

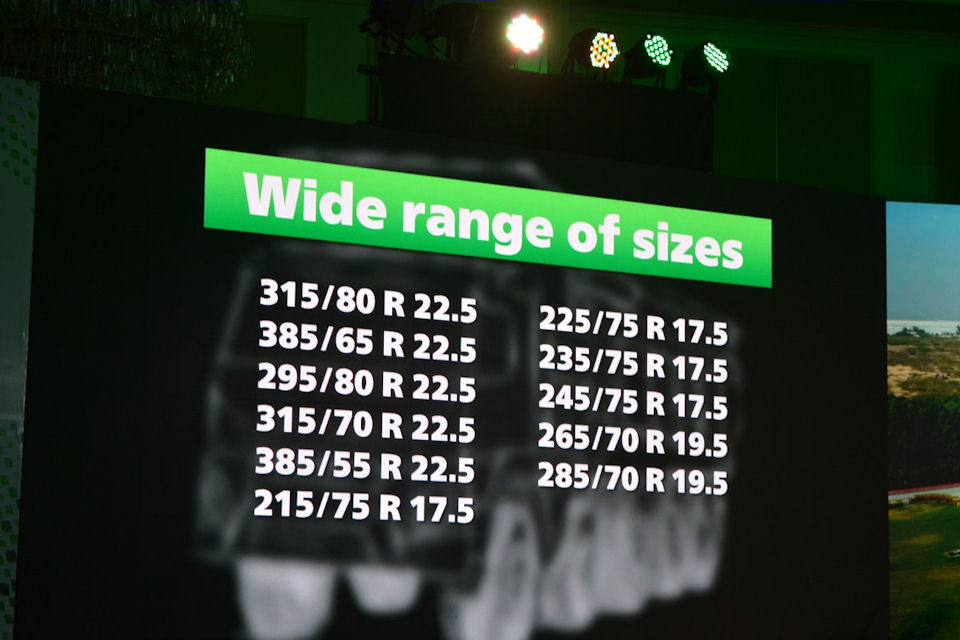

But the biggest news is that BKT will enter the off-highway truck tyre segment and offer a wide range of sizes from early 2025. These tyres, like all other new products, will be manufactured in Bhuj. “This is a unique opportunity for our company. We are capitalising on the expansion of our mining range, having the technology, experience and industry knowledge from years of work. We are ready for this challenge.”

Initial sizes in BKT’s off-highway truck range (Photo: Pneusnews.it / Ludovico Bencini)

Energy & carbon black

An increase in production of this magnitude requires additional energy and carbon black. At the newly-expanded Bhuj site, BKT will expand the power plant from 40 megawatts to 60 megawatts, with the extension to the power plant fuelled by natural gas rather than coal. A photovoltaic plant producing 1 MW is already in place, and BKT plans to increase this to 5.5 MW.

As for carbon black, this is a highly strategic raw material for BKT. In 2019 the plant produced 65,000 tonnes per annum but increased this to 110,000 tonnes the following year, an amount meeting plant requirements. The breakthrough came in 2021, when the company produced 148,000 tonnes and started selling the surplus to other tyre manufacturers. It produced 165,000 tonnes last year and aims for 200,000 tonnes in 2023.

Expansion plans will see the annual capacity for carbon black rising by a further 300,000 tonnes. As mentioned earlier, in practice Bhuj is no longer just a tyre factory, as over the years carbon black has become an alternative business that is expected to account for five per cent of BKT’s total turnover.

More employees, extra facilities

Increasing production capacity requires space, energy, raw materials – and people. For this reason, BKT also has important plans in terms of human resources. In addition to employee housing, the current Bhuj site contains shops, schools, medical facilities and a gymnasium. A total of around 4,600 people live at the site, including 3,600 employees. With the expansion, this will increase to around 5,000 workers and 1,240 family members.

And that isn’t all. The site’s existing training centre, where up to 80 people can engage in technical, motivational and leadership courses, will be complemented by an international school. BKT views this facility as a a real “investment in the future” as it will provide a complete training and sports programme, with dedicated facilities, high-quality education in different languages, such as Spanish and German, and also study abroad programmes.

BKT will additionally organise adult education programmes, in this case in local languages. This company anticipates that the school will be a major boost to the local economy as jobs will be created for staff and teachers.

This article originally appeared on our Italian sister site pneusnews.it

Comments