Carbon Air technology uses coconut shells to reduce tyre noise

Carbon Air reports that it has introduced its technology to automotive air suspension systems on premium variants of the Audi A6 and A7 (Photo: Carbon Air)

Carbon Air reports that it has introduced its technology to automotive air suspension systems on premium variants of the Audi A6 and A7 (Photo: Carbon Air)

Manchester-based Carbon Air is introducing a patented application of coconut shell-derived material in order to help alleviate road noise from tyres. According to the company, the technology is aimed at reducing the noise of both internal combustion engine cars and electric vehicles (EVs).

However, the intrusion of road noise into a car’s passenger cabin is being exacerbated in EVs because, without an engine to mask tyre sound, some motorists are experiencing more noticeable droning sounds from the wheels for the first time.

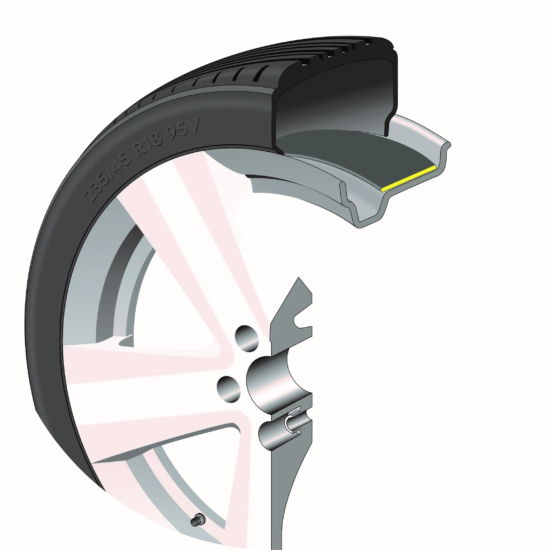

Carbon Air’s research has found that activated carbon applied to a wheel rim, significantly reduces the resonance generated in the wheel cavity. Carbon Air’s solution is more durable and cost-effective since it will remain on a rim and with the car for life, not just until the tyres are replaced.

In its laboratory testing, Carbon Air’s research and development team found a 15 dB reduction in peak tyre cavity resonance (at just over 200 Hz, the typical frequency of a tyre driving on a tarmac road). The company reports that it is at “advanced stages” of discussions with wheel suppliers and vehicle manufacturers to introduce the technology in forthcoming products.

John Coakley, Chief Technology Officer at Carbon Air, said: “This breakthrough application will revolutionise the future of automotive comfort and refinement. With cars getting quieter, there is a noticeable and constant drone from the tyres. This only gets worse as the speed of the car increases. Thanks to our material, car makers can reduce cabin noise significantly, increasing the perception of quality engineering, and thereby reinforcing the much sought-after sense of premium to differentiate them from their competition.

Following the successful introduction of its technology to automotive air suspension systems on premium variants of the Audi A6 and A7, Carbon Air is already expanding its patented applications of activated carbon. In 2022, Carbon Air successfully launched its commercially available activated carbon insert for mountain bike air suspension forks and is at the advanced stages of developing numerous acoustic applications.

Activated carbon is formed by subjecting organic carbon matter, such as coconut shells, coal and sawdust, to super-heated steam and chemicals. This process creates a dense network of microscopic pores, or nanopores, which can vary in type according to the source material being converted. These differences cause significantly differing behaviour in the adsorption of air, which can be enhanced and tuned to a particular application. For acoustic control applications, the nanopores in the activated carbon material are highly effective in dispersing sound energy (waves of air molecules) at low frequencies, and hence reduce the resulting noise heard.

Galgo

Galgo Point S

Point S

Comments