3D printing to reduce Hankook’s production costs

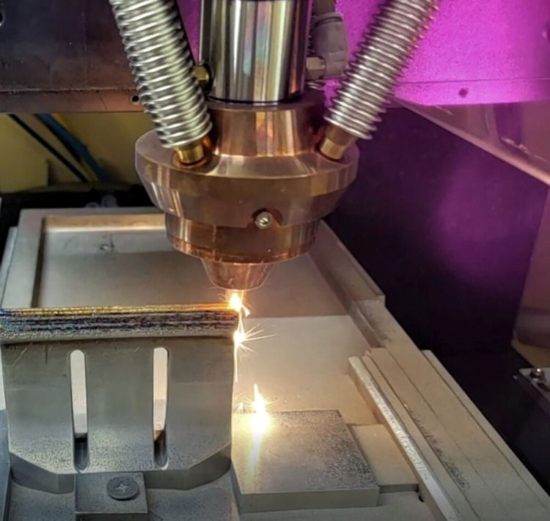

Blunt titanium alloy blades can be restored using Damaged Parts Restoration 3D Printing Technology (Photo: Hankook)

Blunt titanium alloy blades can be restored using Damaged Parts Restoration 3D Printing Technology (Photo: Hankook)

Hankook Tire is set to reduce costs and wastage in its production facilities thanks to a research collaboration with Korea Atomic Energy Research Institute and HM3DP, a 3D printing start-up. Working with these partners, Hankook has developed ‘Damaged Parts Restoration 3D Printing Technology’, which it will use to restore titanium alloy blades that are damaged while cutting tyre rubber during the production process.

Damaged Parts Restoration Technology is a spin-off of a 3D printing technology originally developed for high-performance components employed in nuclear reactors. Hankook Tire explains that the technology uses Directed Energy Deposition (DED), a method of 3D printing that employs a focused energy source, such as a plasma arc, laser or electron beam, to melt a material that is simultaneously deposited by a nozzle.

Titanium alloy blades are significantly more expensive than their stainless-steel counterparts, and in the past Hankook had to inevitably discard these blades when they became worn or damaged from cutting tyre rubber containing a significant quantity of hardening agents. The DED process now allows for their repair.

“Through the implementation of this technology, Hankook Tire has also made a significant contribution to creating an eco-friendly, carbon-reducing parts manufacturing industry, contributing to the company’s corporate social responsibility by reducing carbon emissions generated during parts manufacturing,” reports Hankook. “The blades, which were repaired using the additive 3D printing technology, are currently installed and are under verification at the production facilities in Hankook Tire’s Daejeon plant.”

Ongoing innovation

This is not the first occasion that Hankook Tire has applied 3D printing technology. The company introduced 3D metal printers in 2015 and even completed a serial production system for engraving 3D sipes on a tyre mould. The company plans to “continue collaborating with domestic and foreign experts to achieve the technological innovation of the cutting-edge manufacturing technology of 3D printing.”

Meanwhile, Hankook Tire is innovating through collaboration in other fields. The company has teamed up with KAIST (Korea Advanced Institute of Science and Technology) to jointly research digital technology capabilities and innovative R&D through Digital Transformation. It also carried out a cooperative development project, Road Hazard Prediction & Detection Solution, with SK Planet to anticipate potential hazards by identifying road conditions through artificial intelligence and deep learning technology.

Comments