SRI investigating vulcanisation to improve tyre performance

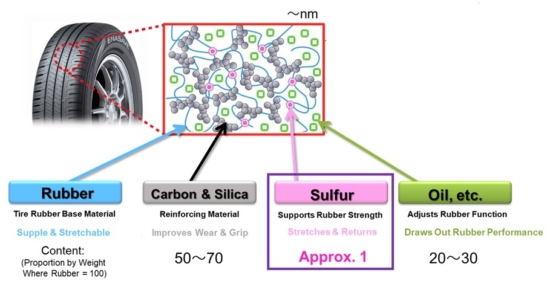

As sulphur only accounts for 1% of the raw materials in rubber, its impact on tyre performance has long been overlooked (Image: SRI)

As sulphur only accounts for 1% of the raw materials in rubber, its impact on tyre performance has long been overlooked (Image: SRI)

Sumitomo Rubber Industries (SRI) frequently shares details of joint work on new technologies that might lead to better tyres. The manufacturer of the Falken tyre brand recently provided an update on research undertaken together with Professor Yoshitaka Ishii from the Tokyo Institute of Technology and visiting researcher Muneki Ouchi from research institution Riken, reporting that the partners have “shed new light on the mysteries” surrounding the rubber vulcanisation process in tyre production. This knowledge may help SRI “further improve overall tyre performance” in future.

The vulcanisation process involves chemical reactions between raw rubber and sulphur under intense heat and pressure. Focusing on the chemical bonds that form between natural rubber and sulphur through these reactions, the SRI research team has now succeeded in detecting the presence of ring structures, which potentially influence the fundamental performance of tyres. The partners now intend to develop new techniques that will allow them to “adeptly control the bridge structures and ring structures that fill in and connect the gaps between natural rubber molecules.” As mentioned, they will then utilise this technology to improve tyre performance.

Uncovering ring structures

The sulphur bridge structures formed during the vulcanisation process provide elasticity to rubber and thus play a major role in tyre performance. But as sulphur only accounts for around one per cent of the raw materials that constitute tyre rubber, prior research has provided little information about the chemical bonds that form between rubber and sulphur. The research carried out by SRI and its partners is the first to detect the presence of ring structures.

The Sumitomo Rubber Group intends to apply the results of this research to accelerate the Development of ‘Performance Sustaining Technology’, one of the core technologies of its Smart Tyre Concept for developing future tyres and peripheral services.

The results of this research were published in the 25 October 2022 issue of Biomacromolecules, which is an academic journal published by the American Chemical Society.

Comments