SRI tyre research benefits lithium-sulphur battery development

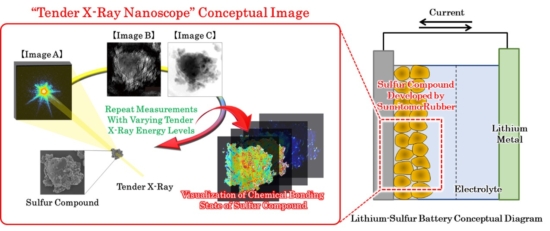

Sumitomo Rubber Industries (SRI) and its research partners have developed a technology for measuring the structure and chemical state of matter at a nanoscale level. They have employed this Tender X-Ray Nanoscope technology to visualise the sulphur compounds within lithium-sulphur batteries in greater detail than ever before. SRI anticipates not only improving the performance of lithium-sulphur batteries currently under development – the technology may also lead to better-performing tyres.

The breakthrough is part of joint research that SRI has conducted with Professor Yukio Takahashi from the International Center for Synchrotron Radiation Innovation Smart at Japan’s Tohoku University and Yusuke Tamenori, director of the Japan Synchrotron Radiation Research Institute. When developing the Tender X-Ray Nanoscope, the researchers worked with Spring-8, the world’s largest third-generation synchrotron radiation facility.

SRI has long been actively engaged in research involving sulphur, a major raw material in tyres that significant influences both the performance and longevity of these products. In the hope of applying the knowledge accumulated through tyre research in other fields, the company began participating in joint research and development into lithium-sulphur batteries with Japan’s National Institute of Advanced Industrial Science and Technology in 2011.

High capacity, problematic cycle life

Not only do lithium-sulphur batteries have an expected theoretical capacity six to seven times greater than conventional lithium-ion batteries, they are also lighter and safer to use. On the other side of the equation, lithium sulphur batteries have a poor cycle life, a factor that has hindered their commercialisation. Improving cycle life will require extremely high-precision measurements of sulphur compounds such as those performed by the Tender X-Ray Nanoscope.

From 2024, SRI will also utilise the new NanoTerasu 3GeV-class Synchrotron Radiation Facility, currently under construction at Tokohu University, to measure lithium-sulphur batteries under charge-discharge cycling. These measurements will aid the search for further practical applications for this technology in the field of materials development. In addition, SRI is looking to apply this technology in its tyre research activities, including a deeper analysis of the crosslink structure chemically bonding rubber and sulphur.

“We are confident that these efforts will contribute to the development of Performance Sustaining Technology, which is one of the key technical development themes of our Smart Tyre Concept for the development of future tyres and peripheral services,” states SRI.

The results of this research were published in The Journal of Physical Chemistry C on 11 August.

Falken

Falken Anvil Tyres

Anvil Tyres

Comments