70 years of Kirkby Tyres

J Rose Tyres’s original Kirkdale Road premises (Photo: Kirkby Tyres)

J Rose Tyres’s original Kirkdale Road premises (Photo: Kirkby Tyres)

Chairman Gorden Rosenthal talks tyres, crisis management, industry awards and offers advice for the next generation

Liverpool-based Kirkby Tyres has played a leading role in the UK tyre business for much of its post-war history. Much has changed during that time, so with Kirkby Tyres’s parent company celebrating its 70th anniversary this year, Tyres & Accessories spoke to chairman Gordon Rosenthal in order to find out more about the past, present and future of the well-known tyre wholesaler.

Tyres & Accessories: J Rose Tyre Group, the parent company of Kirkby Tyres, celebrates its 70th anniversary this year. That’s an impressive milestone. What’s the secret to the company’s longevity?

Gordon Rosenthal: I believe there are three elements to our staying power. Firstly, our people. We have a dedicated and long-serving team. One of the most experienced in our industry. For example, our sales, purchasing, quality control, hr and warehouse stock manager have over 150 years with the company between them, in addition to my own 45 years with the company. This represents a framework of expertise, plus a keen team with knowledge of the right quality product to sell. The whole team shares a reputation for efficiency of distribution allied to first-class products.

Talking about supply of products, we have very long-standing relationships with our own suppliers, Alliance, BKT, Double Coin, MRL, Nankang and Sailun. These relationships alone stretch to over a combined 160 years, backed up with prompt payments and market feedback from us. This helps us to continue to bring innovative products to market from each supplier.

Regarding products, we don’t operate at the budget end of the market as other importers do, believing this adds no value to the industry, rather it just drives down prices for the trade. Alongside this, I think switching brands regularly also does not favour our customers. Talking about customers, our loyal customer base is another element to our success and by only dealing with the trade and marketing a value-adding stable of brands, we look to help the tyre dealer obtain better sales margins of their own.

Regarding milestones, it was great to have our hard work recognised at the NTDA awards ceremony over the last few years, having received the award for either Wholesaler of the Year or Truck & Agri Supplier of the Year for the last five years consecutively. I think this offers a reflection of the value our activities add for our employees, suppliers, customers, Kirkby and importantly, the industry. With so many ongoing investments and exciting developments happening at Kirkby we have decided to direct a little more time to helping to realise some of those developments (such as in IT and distribution) and haven’t entered for the awards ceremony this year, although we will be back with an application next year for sure!

T&A: What are some of the most significant changes you have you seen in your time with the business? Perhaps historically and more recently?

GR: I think historically the change from cross-ply to radialisation in truck, tractor, earthmover, and car was a significant moment in the industry. In my time in the business, I do also recall a trend (over time) of manufacturers trying to move down the value chain and become involved in wholesaling and distribution. I think almost all the premium manufacturers followed this strategy, with most, if not all of them, failing to make it work. It’s noticeable that this trend has come full circle in recent times, with the presence of online operators and direct selling by the majors (via their own online platforms) and large operators previously never involved in the tyre business, i.e. Amazon, eBay etc.

T&A: What have been some of the significant challenges the company has faced and how have you met them?

Kirkby Tyres has always specialised in truck, bus, agricultural and off-road tyres (Photo: Kirkby Tyres Ltd)

GR: Certainly, some of the most significant challenges that have materialised in the last few years have been Brexit and Covid-related. Regarding the former, it certainly appeared that nobody at the governmental level was prepared with regards to administration and documents required for imports and exports, from outside and within Europe. Regarding Covid and the shock to the global supply system, which we are still feeling now, I have never seen such supply chain issues and problems which are all well documented, not just for the tyre industry, but any manufactured goods. Throughout the early Covid period we saw massive shortages in all product segments and incredibly restrictive freight rates and availability. To lessen the impact of these challenges on our customers and the company during that period, we continued to work closely with our suppliers and freight partners to import and hold as much stock as possible.

T&A: How would you assess the current economic/business climate, particularly for tyre importers, distributors and retailers and the off-highway segments?

GR: I have noticed the marketplace is becoming considerably tighter. Original equipment manufacturers (OEMs) are now not panicking as much for supply (as we saw during the early Covid period). I think the recent hike in interest rates (and more to come), with the current rate being a lot higher than pre-Covid, is causing large construction and plant companies to review projects, project financing and their own capex commitments, with all now drawn back (with some projects on hold or under review).

Tyre manufacturers seem to be catching up on back orders that built up during early Covid, whilst demand in the market is softening quickly, where it may be that the balance between supply and demand that we saw in the early Covid period will be reversed very quickly in the next six months. Indeed, we can already sense this in the marketplace (having received feedback from our own customers). Regarding farming, we have a combination of uncertainty regarding government support following Brexit, together with a record dry summer where new tyres are not required in the fields.

T&A: What do you think Kirkby’s current strengths are and how will you combat current challenges?

GR: Whilst we are of significant size and stature within the marketplace for TBR and off-highway tyres and wheels, we do make decisions very quickly and very decisively are able to react to market conditions. In addition to this flexibility, we consider that the best way to support our customers is via our central distribution model. In line with many European importers and distributors, we moved away from a model of smaller satellite warehouses a long time ago. This way we ensure that we not only have the broadest range of product to offer from one central location (not possible with smaller geographically spread warehouses), but we can also take advantage of our distribution partners’ investments in routing, green vehicle technology and IT advancements. Indeed, we are constantly in liaison with our delivery partners to improve on our current offer of next-day delivery throughout the UK.

Technology wise, we continue to invest and innovate alongside our supply and transport partners. Currently in the middle of a migration to a new ERP, which should be realised in 2023, this should help to crystalise further efficiencies and possibilities that we can offer our customers. Marketing wise, we continue to help our customers with creative and industry leading initiatives such as our innovative TyreSync project whereby we can build a website and product catalogue for our customers (in their own colour scheme and branding). At the same time, we are adding experience to an already impressive management team, with an increase in responsibilities for key members of the team. For example, this year sees Robin Walls become our new finance director, Michael Rosenthal our new commercial director, and Carl Lee our new operations director. These new positions will help the team steer us through unchartered waters (and situations we have seen before).

Regarding infrastructure, we have now increased our existing site and current warehousing under operation in the UK to a now impressive 440,000 square feet. This will allow us to meet the challenges presented by global shocks by holding even greater stocks of the right products at the right time for our customers. Our recent 4 million euro investment into new facilities in Dublin, covering over 60,000 square feet will allow us to continue to expand our product offering in the Irish market, now recently including the full range of Maxxis and CST branded ATV and turf tyres.

T&A: What are some of the lessons from your time in the business and what advice would you impart on the next generation of tyre entrepreneurs?

You never stop learning in this business! Some of the lessons I have taken on board include (but are not limited to) the following: Market and business trading conditions can change very quickly, almost overnight. People in the tyre business are far too quick to reduce new products to commodity price levels. With all the technical expertise that goes into the research and development and production of a new tyre, they are still very often sold like a tin of beans – i.e. whoever is the cheapest gets the order! No consideration is given to the above points or the level of service that is provided post-sales. We are constantly striving as a company to create added value for our suppliers, our customers and ourselves. And finally, there is no substitute for hard work and experience!

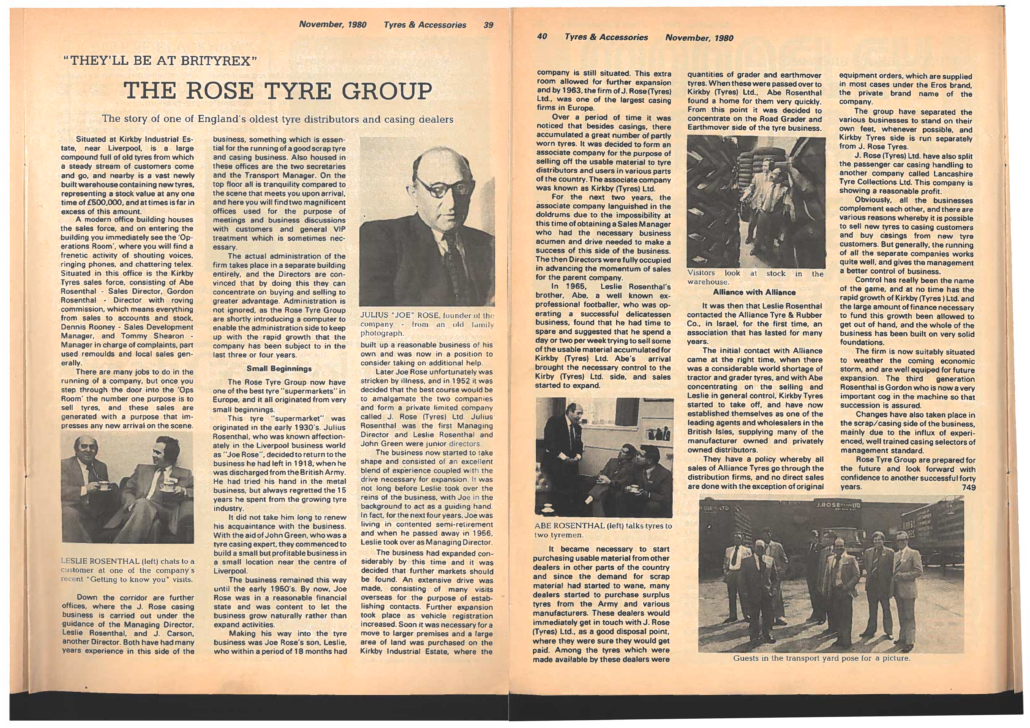

As this November 1980 Tyres & Accessories article demonstrates, Kirkby Tyres has been playing a leading role in the UK tyre business for much of its post-war history. And what’s more, again demonstrated in the archive text, the company benefits from some of the most experienced personnel out there (Image: Tyre Industry Publications Ltd.)

Policy Exchange

Policy Exchange

Comments