Goodyear launches GP-3E for infrastructure applications

GP-3E is said to offer innovations that reduce operator costs, while enhancing performance (Photo: Goodyear)

GP-3E is said to offer innovations that reduce operator costs, while enhancing performance (Photo: Goodyear)

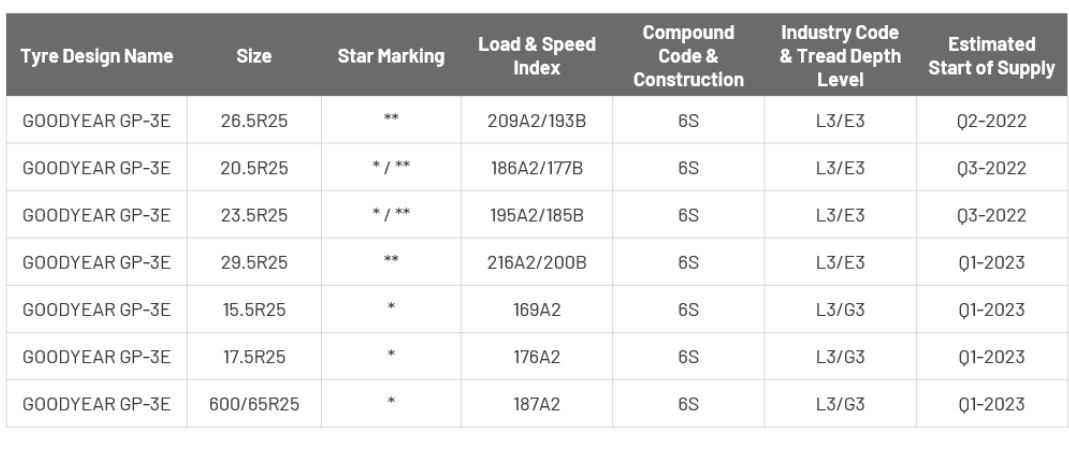

Wheel loaders, articulated dump trucks and graders are typically used on major infrastructure projects that have tough cost and timescale targets. After researching operator requirements, Goodyear has introduced a new tyre for these vehicles, GP-3E. It says the increased the operational versatility of its latest tyre generation makes “tyre choice easy for the operator.”

Goodyear has vast experience in servicing vehicles in the L3 (loader and bulldozer), E3 (earthmover) and G3 (grader) segments. While there are significant differences between these machines, similar demands are placed upon the tyres they wear.

Maximising margin in a competitive sector is important for operators. Goodyear states that GP-3E offers innovations that reduce operator costs, while enhancing performance. For example, the tyre features Goodyear’s specially formulated Type 6 compound which has advanced abrasion resistance, reducing operators’ tyre costs.

GP-3E weighs less than its predecessors, boosting efficiency. But Goodyear stresses that this weight reduction does not come at the expense of strength and durability, as the GP-3E features a new multiple steel belt casing construction that has enhanced cut and tread wear resistance. The tyre maker adds that this construction has been proven to optimise tread wear, helping achieve Goodyear’s goals of maximising efficiency and sustainability without compromising performance.

Traction and flotation

Another area where Goodyear tackled the challenge of seemingly conflicting priorities during operations was in the areas of traction and flotation. From a tyre engineering perspective, traction delivers grip for forward motion, but needs to be balanced with flotation, which helps the machine keep on top of the surface without creating damage or becoming bogged down.

The GP-3E tread pattern achieves high levels of traction with additional biting edges, dual centreline lugs and an increased lug count. At the same time, the tread is designed to support a high level of flotation by distributing weight evenly.

Another claimed benefit of this enhanced tread pattern, combined with the new construction, is improved levels of operator comfort. Goodyear says it designed GP-3E to reduce vibration levels, particularly on hard surfaces. This is predominantly important for operator welfare on long shifts in challenging climates.

Goodyear’s Electric Drive Ready philosophy means the company’s latest tyres are fit for use on electric, hybrid and conventional diesel machines. This reduces operator stocking requirements as the same tyre can be used, whatever the motive power.

Simplifying the choice

“Goodyear has listened to the needs of operators in this demanding sector,” comments Octavian Velcan, managing director Goodyear OTR and Aviation EMEA. “Reducing cost and maximising uptime are industry priorities. By introducing one versatile, efficient and durable range fitting the operational demands of a wider range of machines we are simplifying the choice, maximising efficiency and bringing innovations that enhance tyre versatility. The innovative lightweight design of the new GP-3E supports an optimised cost per hour which drives efficiency and promotes sustainability. But it also means low-vibration comfort for the drivers.”

Comments