Better tyres – SRI says research “opens door” to rubber bioengineering

Source: SRI

Source: SRI

Sumitomo Rubber Industries (SRI) reports progress in its joint work with professors from three universities to improve natural rubber yields and create new strains of rubber that will enhance tyre performance.

Working with Associate Professor Seiji Takahashi of Japan’s Tohoku University, Associate Professor Satoshi Yamashita of Kanazawa University and Professor Yuzuru Tozawa of Saitama University, SRI has identified the segment of the natural rubber synthase that plays an important role in controlling the length of natural rubber polymer chains. By recombining this segment, the research team successfully synthesised a biopolymer “not found in nature” with a structure differing from that found in natural rubber but nevertheless featuring a chain length comparable to natural rubber.

“Moving forward, we will continue this line of research in the hope that it will lead to improved natural rubber yields as well as the creation of new strains of natural rubber that will contribute to improvements in overall tyre performance,” states SRI.

Segment swap to modify enzyme

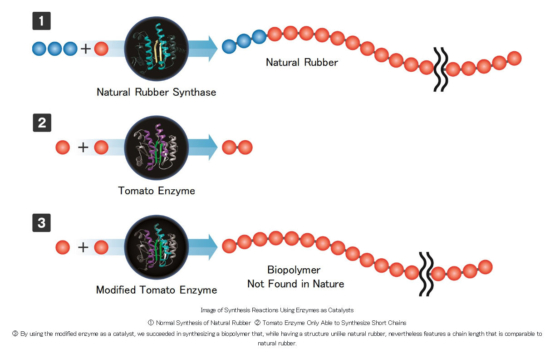

The partners discovered the segment affecting chain length by comparing the structures of enzymes involved in the synthesis of natural rubber (long chains) with the structures of enzymes involved in isoprene chain synthesis of tomatoes (short chains) as both of these enzymes belong to the same enzyme group and share similar structures. They then found that replacing this segment of the tomato enzyme with the same segment from the natural rubber synthase resulted in a modified enzyme that synthesised polyisoprene with chain lengths comparable to natural rubber.

“The use of this modified enzyme allowed us to utilise a starting substrate that is unlike natural rubber synthase in order to successfully synthesise a biopolymer not found in nature as the product of the resulting synthesis reactions,” SRI explains.

SRI announced the results of its research at the DKT IRC 2021 exhibition and conference in Germany, which belatedly took place this week. Moving forward, the Sumitomo Rubber Group says it intends to “continue working to contribute to the realisation and prosperity of a sustainable society through our ongoing efforts to ensure a stable supply of natural rubber while providing tyres that combine safety and peace of mind with reduced environmental impact.”

Comments