VMI introduces Revolute bead apex assembly system

Revolute “opens up new options for tyre design and performance” (Image: VMI)

Revolute “opens up new options for tyre design and performance” (Image: VMI)

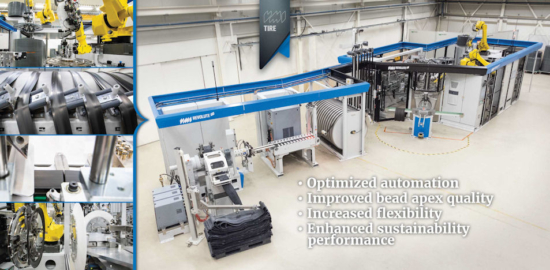

VMI has launched a new automatic bead apex assembly system designed to complement its existing bead apexing solution. This addition to the range is called VMI Revolute, and the machinery manufacturer says it offers users the advantages of optimised automation, improved bead apex quality, increased flexibility and enhanced sustainability performance.

According to VMI, Revolute boosts production time per item to almost double that of its next best performing system. Furthermore, the manufacturer says Revolute “opens up new options for tyre design and performance” whilst delivering increased levels of automation, allowing as it does for a higher apex than any other unit on the market as well as a greater variety of compounds.

Revolute shortens changeover times, with much less operator intervention and greater use of recipe-driven methods. VMI adds that waste is reduced, quality is more consistent and processes are made more efficient when using Revolute. The result is increased productivity and flexibility as well as improved competitiveness.

Comments