Racetrack debut for guayule rubber tyre

Racing on Firestone Firehawk tyres will commence in August (Photo: Bridgestone)

Racing on Firestone Firehawk tyres will commence in August (Photo: Bridgestone)

Several tyre makers plan to offer tyres containing natural rubber from non-conventional sources. Bridgestone Americas has been working to commercialise guayule shrub rubber for a decade and recently announced the upcoming motorsport debut of a race tyre made with guayule rubber grown and extracted at its R&D facilities. It will introduce the new Firestone Firehawk at the Indy Pit Stop Challenge on 27 May ahead of the race tyre’s competitive premiere in August.

In addition to supplying guayule race tyres, Bridgestone will also partner with Penske and Indianapolis Motor Speedway (IMS) to transport all Firestone Firehawk race tyres to IMS via a Freightliner eCascadia from Penske Truck Leasing’s fleet of electric vehicles during the month of May. IMS has installed a 150kW high power electric charging station at the track to allow for convenient charging.

“The introduction of guayule natural rubber to America’s preeminent open-wheel racing series speaks to the confidence we have in the technology and its promise as a scalable, sustainable and domestic source of our industry’s most vital raw material,” says Nizar Trigui, chief technology officer and group president, Solutions Businesses, Bridgestone Americas, Inc. “It will take partnership and collaboration to combat the impacts of global climate change and we are proud to partner with Penske, Indycar and IMS to advance the future of sustainable mobility.”

Potential lasting impact

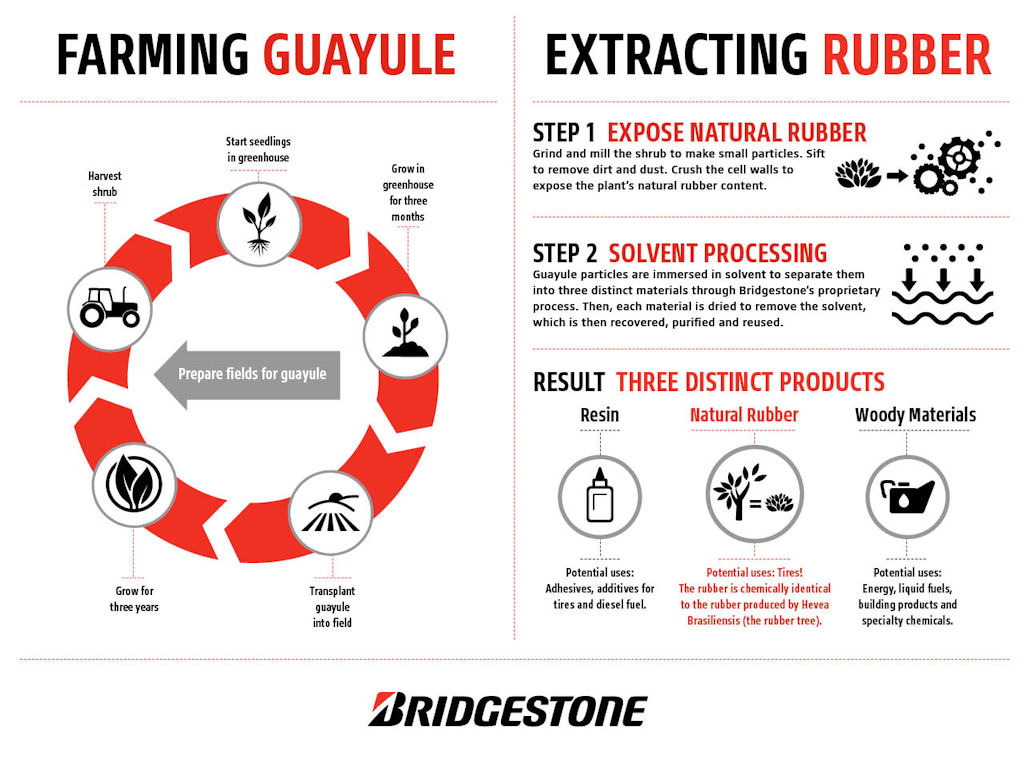

Bridgestone aims to commercialise the use of sustainable guayule natural rubber in tyres by 2030, creating a promising new domestic industry in North America. Guayule is a heat tolerant, woody shrub that thrives in America’s desert southwest. The shrub can be farmed with existing row crop equipment, and Bridgestone shares that guayule creates up to ten new industrial processing jobs per 1,000 acres of harvested crop.

According to Bridgestone, guayule rubber “has the potential to have a lasting economic impact, while reducing the energy and other environmental impacts associated with the transportation of rubber sourced overseas.”

The tyre maker launched its guayule research initiative in 2012, when it broke ground on a guayule processing and research centre in Mesa, Arizona. Today, the company operates the research centre in Mesa, as well as a 281-acre guayule farm in Eloy, Arizona. Bridgestone has invested more than US$100 million in its efforts to commercialise guayule, achieving major milestones such as producing the first tyre made from guayule-derived natural rubber in 2015, and continued expansion of its guayule molecular breeding programme.

Guayule is part of the Bridgestone plan to achieve carbon neutrality and make tyres from 100 per cent renewable materials by 2050. The company is actively researching a range of solutions to support the recycling of materials from end-of-life tyres and promote the replacement of non-renewable materials such as oil, silica and virgin carbon black in new tyres.

Comments