Pelletiser aiding Pyrum’s rCB processing

The pelletiser aids the transformation of raw carbon to rCB (Image: Pyrum Innovations)

The pelletiser aids the transformation of raw carbon to rCB (Image: Pyrum Innovations)

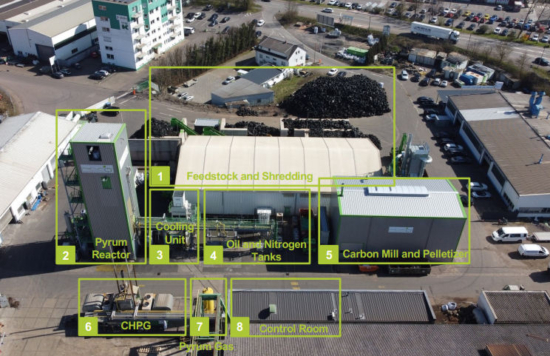

In addition to gaining ISO 9001 certification, Pyrum Innovations has started test operation of a new pelletiser at its plant site in Dillingen, Germany. The pelletiser enables the recovered carbon black (rCB) obtained via the pyrolysis process to be bonded into pellets, which increases their transportability and facilitates the further processing of the raw material.

For example, the pelletiser enables the rCB to be transported as bulk material in trucks, eliminating the need for packaging, and to be resold to various industries, including large tyre manufacturers whose production processes often only allow the acceptance of rCB pellets. This also increases the price that can be obtained for Pyrum for the rCB produced. After the shredder, the thermolysis reactor and the rCB mill, the pelletiser, the last missing component of the pyrolysis plant, was put into operation.

“With the pelletiser, which has already been running in test mode since Easter, we can now demonstrate the operation of a Pyrum pyrolysis plant from start to finish in continuous industrial operation,” says Pascal Klein, chief executive officer of Pyrum Innovations. “We have also already sent several hundred kilogrammes of the rCB pellets to laboratories to have the quality certified. According to plan, the pelletiser is scheduled to start commercial operations in the fourth quarter of the current year. However, given the milestones already achieved, we currently assume that an earlier regular operation is possible.”

Carbon black is used as a raw material in numerous industries, including in tyre manufacture. Since the start of the war in Ukraine and the subsequent sanctions imposed on Russia, Pyrum Innovations AG has recorded significantly higher demand for its rCB. Before the conflict began, around 60 per cent of the carbon black processed in Pyrum’s home market of Germany was imported from Russia, but in recent months Pyrum has received an increasing number of enquiries from industries that it didn’t previously identify as potential customers. With the expected commissioning of the pelleting plant this year and the ongoing expansion of its site in Dillingen, Pyrum expects to be able to increase its production capacity in the coming quarters.

Comments