Dymag & Hankuk Carbon partner to produce carbon composite rims for OEMs

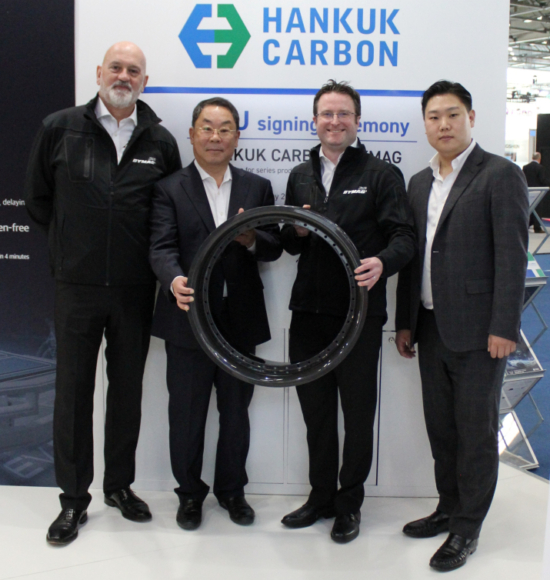

(l-r): Chris Shelley, executive chairman at Dymag; Moon-Soo Cho, CEO at Hankuk Carbon; Tom De Lange, CEO at Dymag; Bill Cho, general director at Hankuk Carbon (Photo: Dymag)

(l-r): Chris Shelley, executive chairman at Dymag; Moon-Soo Cho, CEO at Hankuk Carbon; Tom De Lange, CEO at Dymag; Bill Cho, general director at Hankuk Carbon (Photo: Dymag)

Carbon composite wheel firm Dymag Performance Wheels Ltd has entered into a strategic partnership with advanced composite materials manufacturer Hankuk Carbon Co Ltd to enable the mass production of state-of-the-art high-performance carbon composite wheels for the world’s leading automotive OEMs.

The collaboration, announced yesterday at JEC World in Paris, will leverage Dymag’s brand and experience in manufacturing lightweight carbon composite wheels for high-performance and luxury vehicle manufacturers, together with Hankuk Carbon’s expertise in advanced materials and industrialisation. The partners anticipate that this combination of resources and technical expertise will accelerate time-to-market and enable economies of scale in the manufacturing of carbon composite wheels in series production, with a focus on a uniquely scalable and localised approach.

Dymag & Hankuk

Dymag has been active in the two- and four-wheel segments since 1974, and in 2004 was the first company in the world to commercialise carbon hybrid composite automotive wheels. Its wheels feature a carbon fibre rim with a forged aluminium or magnesium centrepiece. Dymag is also the market leader in the carbon composite wheel aftermarket with over 15 leading brands using its technology.

Hankuk Carbon has been producing composite materials, including carbon fibre textiles and prepregs since 1984. The business has grown into an international provider of composite material solutions, with plants in South Korea and Vietnam and global offices in China, UK and Germany. The company provides specialist material solutions for many composite applications, including LNG storage tanks for marine bulk carriers and Battery Electric Vehicles (BEVs), as well as high-quality prepregs for aerospace, marine and automotive markets. Hankuk Carbon provides total technical support from supply of materials through to engineering and productionising effective composite solutions: Composites – All at Once.

Weight savings versus cast alloy

Together, the two companies will work to scale up mass production of Dymag’s cutting-edge BX-F carbon composite wheel. This technology brings multiple advantages for automotive OEMs across all sectors, from luxury to high-performance, ICE to BEV, offering weight savings in excess of 50 per cent over a traditional cast alloy wheel, but with far greater strength and durability.

Step change benefits include improvements in vehicle range and NVH: two huge advantages that can be applied to all vehicles, but in particular the new breed of luxury EVs, where every gram impacts performance and range, and where the ICE is no longer masking unwanted noises.

Through dramatically reduced unsprung mass, but also a reduced moment of inertia, carbon composite wheels bring benefits to ride and handling too.

With less energy required to accelerate and brake the wheel itself, it is easier to control the rotating mass, in turn making it easier to find an optimum compromise between ride and handling in suspension tuning. Another dynamic benefit is a reduced gyroscopic force thanks to the lightness of the rim itself, which means less steering effort is required.

Carbon composite wheels also bring aesthetic advantages for OEMs; a forged aluminium or magnesium centrepiece offering greater design flexibility than a solid carbon fibre wheel, while Dymag’s unique designs are also proven and tested to OEM standards off-the-shelf.

As a result, the benefits of Dymag’s carbon composite wheels are applicable to traditional high-performance road cars, high-performance and luxury electric vehicles and large SUVs and pickups, which are also becoming increasingly electrified, with Dymag wheels available in sizes of up to 23-inches – rated to 1000kg – with even larger sizes to follow.

Higher volumes & greater efficiencies

“The strategic partnership between Dymag and Hankuk Carbon will enable a step change in the production and supply of state-of-the-art carbon composite wheels to the world’s leading automotive OEMs, bringing not only significantly higher volumes but also greater cost efficiencies via scalable, localised manufacturing,” says Tom de Lange, chief executive officer of Dymag. “The price-point for these wheels will be appropriate for both luxury and performance-oriented versions of road cars, particularly the growing high-end electric vehicle market, thanks to Dymag’s technology benefits in improving EV range and NVH. For all automotive sectors, the dynamic, durability and aesthetic benefits of carbon composite hybrid wheels will become accessible to a larger number of consumers through OEM programmes.”

“We share Dymag’s vision for the growth in the global market potential for high performance hybrid carbon composite wheels and our expertise in composite materials and industrialisation will accelerate this. Together, we will bring automotive OEMs an unrivalled technical and commercial offering for future vehicles,” adds Moonsoo Cho, chairman of Hankuk Carbon.

Bush Tyres

Bush Tyres

Comments