SRI: Testing breakthrough will lead to higher rubber yields

Japanese tyre maker Sumitomo Rubber Industries, Ltd. (SRI) says its collaboration in a research project has resulted in a technique that may improve natural rubber yields and even enable natural rubber biosynthesis within a laboratory.

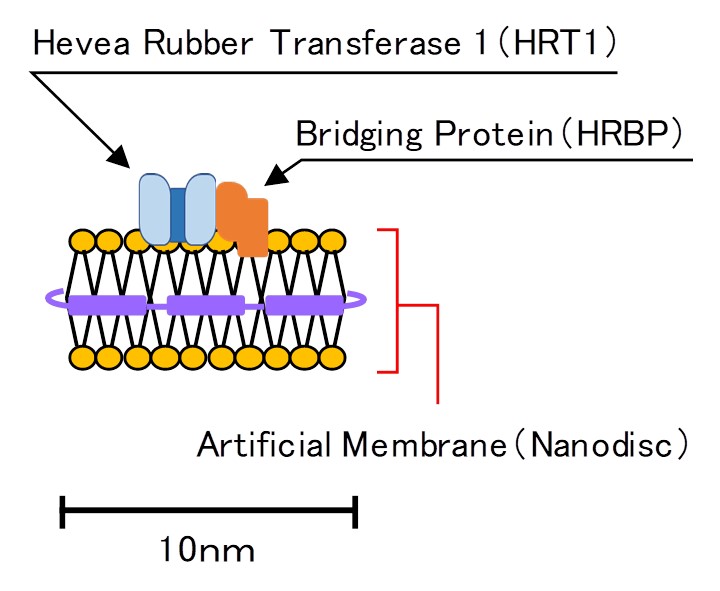

Ongoing joint research with Professor Yuzuru Tozawa of Saitama University, Associate Professor Seiji Takahashi of Tohoku University and Associate Professor Satoshi Yamashita of Kanazawa University into the mechanisms behind the biosynthesis of natural rubber has led to a new technique of employing artificial membranes (nanodiscs) to evaluate enzymes. By selecting artificial membranes instead of the natural ones used in prior evaluation techniques, researchers can eliminate environmental impurities and thus gain more precise results. SRI believes that this “ground-breaking technique” will “surely lead to the improvement of rubber yields and many other advancements, potentially even opening the door to laboratory biosynthesis of natural rubber.”

Protein’s role identified

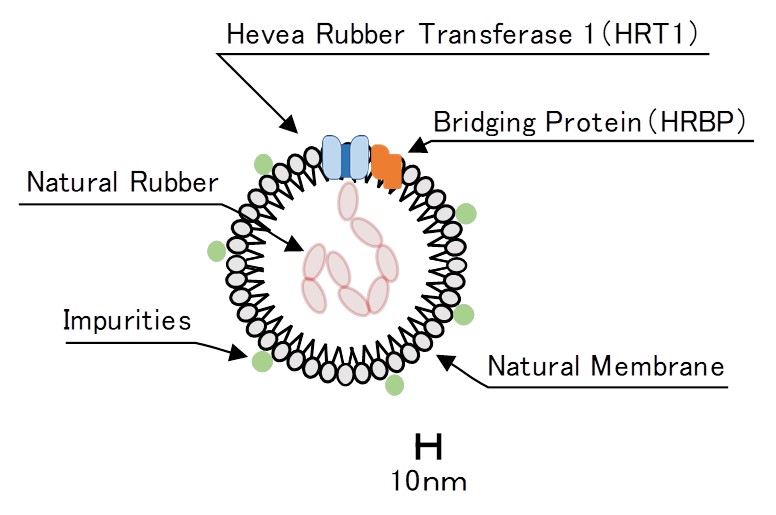

Explaining the science behind this breakthrough, SRI notes that researchers have long known the important role that three specific proteins play in the Pará rubber tree’s rubber biosynthesis process. These proteins are Hevea Rubber Transferase 1 (HRT1), HRT1-REF Bridging Protein (HRBP) and Rubber Elongation Factor (REF). HRBP is a protein thought to facilitate molecular binding between HRT1 and membrane particles that serve as a nexus for the accumulation of natural rubber, whilst REF is a protein believed to play a role in membrane particle stability. HRT1 is thought to bind multiple molecules together, however, it was not clear under what conditions it fulfils this function.

In the past, researchers have observed HRT1 synthesising isoprene chains when placed on natural membranes, such as those formed by rubber particles or yeast. But this testing was compromised by the use of natural membranes, which inevitably contaminated the test environment and made it impossible to identify the other constituents necessary for isoprene chain synthesis.

“And so, we developed a new enzyme evaluation technique that uses artificial membranes (nanodiscs) that contain no natural materials. Thanks to this breakthrough, we have now discovered that HRT1 synthesises isoprene chains when both HRT1 and HRBP are present on one of these artificial membranes. This was the first time that HRT1 has been observed performing this function on an artificial membrane,” shares SRI.

According to the manufacturer of the Falken tyre brand, the research team’s next step will be to find the significant component (+α) that causes isoprene chains to lengthen. Achieving this step would make it possible to artificially biosynthesise natural rubber in a laboratory.

Results of the research have been published in the journal Scientific Reports.

The prior technique, which was announced in 2016, relied upon a natural membrane (Image: SRI)

A nanodisc now takes its place, enabling researchers to pinpoint the function of HRT1 (Image: SRI)

Halfords

Halfords

Comments