Nexen Tire develops AI-based tyre performance prediction software

Source: Nexen Tire

Source: Nexen Tire

Professors from two South Korean universities have collaborated with Nexen Tire to develop a technology that utilises artificial intelligence (AI) technology to predict tyre performance. The resulting application employs machine learning technology during the tyre concept design stage to more quickly and precisely anticipate real-world properties such as fuel efficiency, noise and handling characteristics.

As obtaining large volumes of high-quality data is critical for machine learning, Nexen Tire worked with Professor Seoung Bum Kim of Korea University and Professor Ki Chun Lee of Hanyang University to create a data pre-processing technology that can detect and replace outliers or irregularities in the obtained data. By utilising data augmentation techniques to secure a substantial amount of learning data, the tyre maker developed a forecasting model that offers good predictive performance even when working with insufficient data.

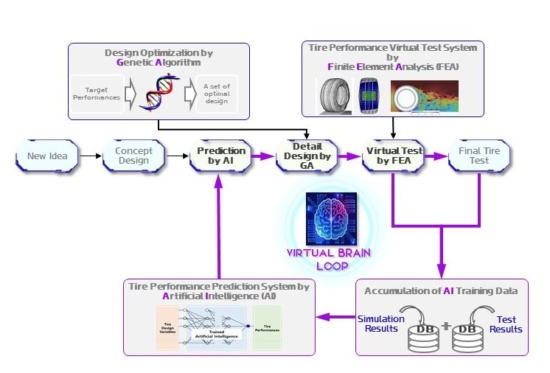

The ability to forecast a tyre’s performance early in the development process significantly reduces the number of physical prototypes that need to be produced later and also shortens the development process. Finite Element Analysis (FEA) is used to produce virtual 3D tyre models that serve as a basis for calculating tyre properties, with these properties confirmed through numerical calculation. FEA results in highly accurate prediction values, but it takes a long time to calculate these figures and developers are thus unable to quickly analyse performance at the concept design stage.

Nexen Tire to the rescue with its Virtual Product Development System. Utilising AI technology, this newly developed tyre performance prediction system allows for speedier and more accurate tyre design and performance improvement during the pre-production process, in addition to the existing FEA-based performance prediction technique and genetic algorithm that suggest optimal design plans.

“We aim to finalise the development of the ‘Virtual Brain Loop System’, a tyre development system based on our own virtual design technology, and apply it to original equipment and replacement goods,” shares Seong Rae Kim, researcher at the Nexen univerCITY, Nexen Tire’s central R&D Institute. “Through combined industry-academic research, we intend to increase talent training and R&D skills.”

Comments