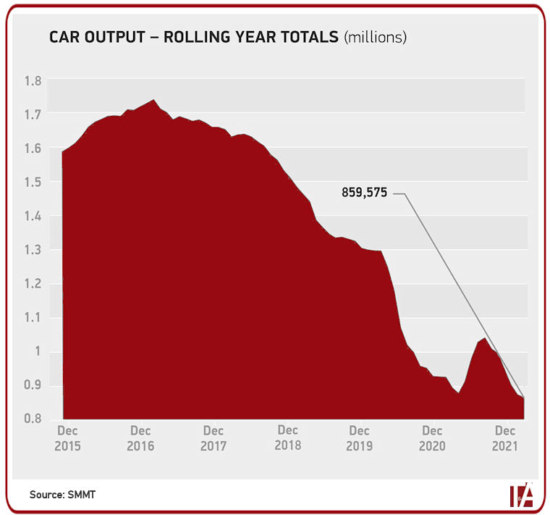

UK 2021 car production 34% below pre-covid level

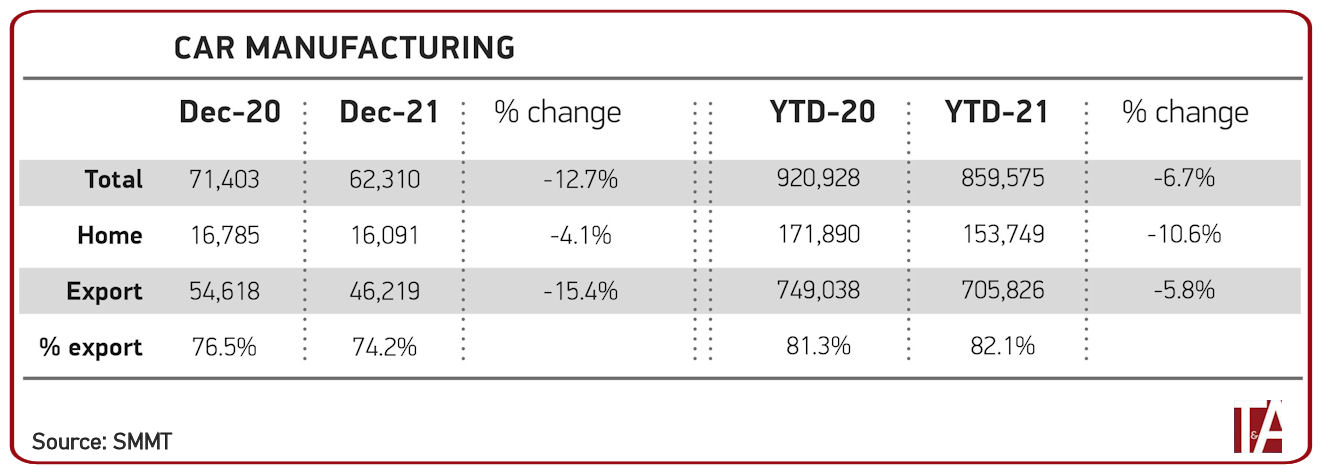

A total of 859,575 cars were produced in the UK last year, 6.7 per cent or 61,353 units fewer than a 2020 that itself was badly affected by lockdowns. Figures from the Society of Motor Manufacturers and Traders (SMMT) show that 2021 production was 34.0 per cent below the pre-pandemic 2019 figure.

Despite this, British car factories produced a record number of battery electric (BEV), plug-in hybrid (PHEV) and hybrid electric vehicles (HEV), turning out almost a quarter of a million (224,011) of these zero and ultra-low emission vehicles, representing 26.1 per cent of all cars made. BEV production surged 72.0 per cent while hybrids rose 16.4 per cent.

The overall poor performance can be attributed to several factors, most of them direct consequences of the pandemic. The shortage of semiconductors, a critical component in modern car manufacturing, was the principal cause of the decline, with factories having to reduce or even pause production while awaiting parts whose supply has been heavily constrained by the global pandemic.

Manufacturers also wrestled with staff shortages arising from the need to self-isolate and depressed demand with car showrooms closed for months due to lockdowns, despite the success of ‘click and collect’ services. There were also non-Covid issues behind this fall, most notably the closure of a major UK car plant in July, which accounted for around a quarter of the annual decline.

Lower decline for exports

Global exports continued to be the foundation for UK car manufacturing, with some eight-in-ten cars made being shipped overseas. Although annual production for overseas markets declined 5.8 per cent to 705,826 units, volumes for the domestic market declined even more steeply, down 10.6 per cent to 153,749.

The European Union remained the UK’s largest market by some considerable distance, increasing to from 53.5 per cent to 55.0 per cent of exports and representing 388,249 units (-3.0% vs 2020), despite frictions and costs arising from the new trading arrangements. While automotive businesses were as well prepared as they could be, an SMMT member survey in April revealed that 91 per cent of firms were spending more time and resource managing UK/EU trade than in 2020.

Shipments to several other major global markets also fell, with the US, our second ranked export destination, down 10.5 per cent and Japan, our fourth largest export market, down 36.1 per cent. China, in third place, fared better, with exports up 0.6 per cent to 57,356 units, reflecting strong market conditions in the country and demand for iconic British performance, luxury and premium car brands. Exports to Canada, Australia and South Korea, however, declined, 5.3 per cent, 31.1 per cent and 29.7 per cent respectively.

Confidence increasing developments

Despite the dismal overall performance, SMMT says there were significant developments that give the industry increased confidence. Following the avoidance of ‘no deal’ and the signing of the Trade and Cooperation Agreement (TCA), publicly announced investment for the industry reached a potential £4.9 billion in 2021, the highest total since 2013. This included vital investment announcements in Ellesmere Port, Halewood, Norfolk, Sunderland and Surrey.

Moreover, a significant proportion of the announced investments was in support of electrified vehicles, with the expansion of existing facilities in the North-East and the proposed development of a new battery gigafactory in the West Midlands. The latter intention represents around half (£2.5 billion) of the total investment sum announced in 2021. Realising such investments will be vital as the UK automotive manufacturing sector is expected to need at least 60 GWh of gigafactory battery capacity by 2030 if it is to remain globally competitive as trading requirements tighten.

This investment must also be matched by a package of measures to ensure manufacturing competitiveness across the supply chain, notably in training and reskilling, technology transition and urgent action to address the UK’s increasingly high energy costs.

Forecasted growth in 2022

Mike Hawes, SMMT chief executive, said: “2021 was another incredibly difficult year for UK car manufacturing, one of the worst since the Second World War which lays bare the exposure of the sector to structural and, especially, Covid-related impacts. Despite this miserable year, there is optimism. With Brexit uncertainty largely overcome with the TCA deal, investments have been unleashed, most of which will help transform the sector to its zero-emission future. This is a vote of global confidence in the UK but must be matched by a commitment to our long-term competitiveness; support for the supply chain in overcoming parts shortages, help with skills and training and, most urgently, measures to mitigate the escalating energy costs which are threatening viability.”

The latest independent production outlook for 2022 forecasts UK car production to increase to more than one million units, representing a 19.7 per cent uplift on the 2021 total, despite the loss of production in Swindon. With favourable conditions, including an end to the global chip shortage, new models coming on stream and the avoidance of additional trade barriers, car production could continue to climb and reach 1.1 million in 2025, with further growth beyond.

Comments