Modular Beissbarth equipment range helps maximise ADAS opportunity

The rise of Advanced Driver Assistance Systems within the European car parc is a fast-growing trend. Not only are many cars already fitted with ADAS, the standardisation of various forms of ADAS on new vehicles, coupled with their adoption within the fast-growing electrified car parc, ensure that the demand for ADAS-enabled vehicle servicing will continue to rise. Therefore the ability to service increasingly connected vehicles remains the most prominent consideration for servicing equipment suppliers. Everard, the UK distributor of Beissbarth equipment, notes that ADAS recalibration represents a necessary step in many routine maintenance jobs, calling it a natural extension to wheel alignment services. Altering wheel alignment often changes the alignment of sensors and cameras; for ADAS to work as vehicle manufacturers intend, it is vital that these components are carefully and accurately recalibrated.

The latest range of tyre and wheel servicing equipment from the Munich-based brand reflects this change in the market, offering garages a modular, flexible way to address this growing need within the servicing market. The reliance on correctly calibrated sensors and cameras within cars for the reliable operation of collision avoidance, parking assist, active lane departure assistance among others means that wheel alignment has an even greater impact on connected car safety functions. So, it makes increasing sense to connect the equipment needed to service wheels, cameras and sensors. Early in 2021, Everard, which was made exclusive UK distributor of Beissbarth equipment in 2020, introduced Beissbarth’s Q.Lign “web-based” wheel aligner to the UK market. Styled as “the world’s most innovative wheel aligner,” the Q.Lign’s hardware and software are designed to increase the speed and connectivity of wheel alignment, while maintaining accuracy and repeatability.

Beissbarth says that PC based systems can struggle with problems such as vibrations, humidity, temperature fluctuations and dust. The Q.Lign has no traditional PC, which the company says reduces the risk of failure and enables a more tailored and flexible approach. Its “Stream-to-X technology” mirrors the Q.Lign’s software, meaning a wireless device like a TV, laptop or smartphone can be used instead. As a result, the process is more versatile and adaptable to the workshop’s setup. Negating the need for a classic trolley setup also creates more space at the front of the vehicle for related ADAS or headlight calibration work.

The wireless system is powered by high-performance Li-ion batteries, allowing measurements to be conducted at any lift position. As part of the system, Beissbarth’s new Q.Grip smart gripping system for targets allows adjustment between different wheel sizes in less than a second. Its three-arm design ensures a safe hold for accurate results, without any possible slippage or damage to the rims. The Q.Grip enables the use of any target on any wheel. Beissbarth’s redesigned target concept allows the target to be added to an aligner system by scanning the QR code on the back. The auto ID function allows the system to recognise the saved target boards to then pull the correct calibration data for the measurements.

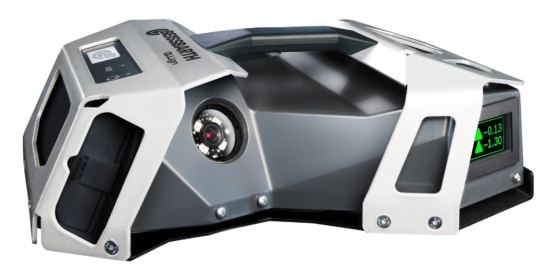

Q.DAS modular FAS calibration

The Beissbarth Q.Lign wheel aligner

Beissbarth’s latest equipment for ADAS calibration is the Q.DAS. The company says the Q.DAS system answers the need for trained technicians, up-to-date, model-specific calibration information, and the ability to fully-document work processes in the calibration of safety-critical driver assistance systems. Beissbarth engineers developed Q.DAS to provide user-friendly, accurate calibration to automotive workshops using the latest ADAS specs from OEMs. It was designed to allow any automotive service technician to safely perform ADAS calibration, even if this is not a daily routine task in the life of the automotive service.

The Q.DAS’s features include: a free choice of calibration targets and radar mirrors; configurations to meet calibration throughput, budget, and space requirements; the use of existing diagnostic solutions; and no lock-in to only one specific diagnostic tester.

The system works with the eTarget digital display for calibration targets with wide vehicle coverage. eTargets use a glass free ePaper screen with reflective technology to ensure high contrast even under extreme light conditions. One eTarget contains 15 target patterns with Q.DAS automatically selecting the correct pattern, increasing the efficiency of this process. The Q.mApp software meanwhile supports the user with step-by-step instructions to correctly setup, position, perform and document the calibration.

asTech

asTech

Comments