ZC Rubber details 5G Smart Factory concept to be installed at pilot plant

ZC Rubber’s Augmented Reality-Aided Equipment Maintenance concept

ZC Rubber’s Augmented Reality-Aided Equipment Maintenance concept

Zhongce Rubber Group (ZC Rubber) is planning to use 5G technology to create a Smart Factory platform for the tyre industry. China’s largest tyre manufacturer says the replicable 5G Smart Factory platform will “promote data network platform innovation and data-driven production process reengineering.” It also says the initiative will enhance “core competitiveness and corporate value through network collaboration, flexible production, and service extension.” The project is currently “in progress and has not yet been officially implemented,” but ZC Rubber plans to implement the concept in its pilot “Future Factory” which is currently under construction. It ultimately wants to extend the technological approach by applying it to more of its factories. ZC Rubber’s headline forecasts indicating the Smart Factory’s predicted benefits include a 15 per cent increase in production efficiency and a need for 70 per cent fewer staff versus existing tyre factory models.

The company said it is developing the platform in response to three tyre industry trends: mass customisation, small-batch production, and unpredictable supply-chain disruption management. It says the 5G Smart Factory will help implement transition from “traditional Business-to-Manufacturer (B2M) to Customer-to-Manufacturer (C2M) and realize smart production and lean management through the Industrial Internet and the Internet of Things.”

Components of the ZC Rubber 5G Smart Factory

ZC Rubber details the various components of its Smart Factory concept in several areas.

ZC Rubber wants to increase the efficiency of equipment maintenance through “human-machine collaboration.” To do this it will use Augmented Reality-Aided Equipment Maintenance to offer visual guidance on equipment maintenance without prior knowledge. It says this will allow junior operators to determine the condition of equipment and complete maintenance under the guidance of AR quickly and accurately. It adds that this method “will help it to maintain equipment at a lower cost and higher efficiency and strengthen process reliability and standardisation.”

The smart monitoring system in ZC Rubber’s smart factory features 4K/8K HD video recording and real-time analytics based on 5G and machine vision technology. For example, in equipment troubleshooting, operators can request guidance from remote experts at any time. The expert team can perform playback, screenshots, and on-demand video signals and send guidance combined with images and voice to the site. Experts can also use various gestures, handles, keyboards, and so on to issue instructions to control the robot’s operation. ZC Rubber says Smart monitoring “will benefit the entire production network with faster decisions and actions to improve the operation process and increase productivity through automation.”

The Smart Factory’s indoor positioning system can display the real-time location of personnel, issue safety warnings, and conduct the emergency evacuation. The company says this system “will help realise indoor navigation, personnel asset management, behaviour analysis, etc., thereby helping our factory save costs, improve service and management efficiency, and reduce or even avoid accidents.”

Predictive Maintenance – an intelligent early warning system – will also be established to determine the operating conditions of plant equipment, allowing the equipment lifespan to be optimised. ZC Rubber says that, combined with data research, this could also provide a comprehensive assessment of the operation conditions of plant machinery and equipment, which helps the factory discover the hidden dangers in time. According to the company, this process, “in the long run, will significantly improve working conditions and increase safety.”

Smart Factory key performance indicator projections

ZC Rubber’s forecasts for the benefits of its 5G Smart Factory project

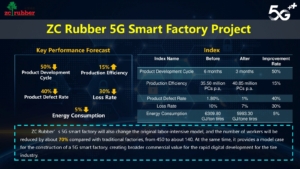

ZC Rubber has outlined its forecasts for the Smart Factory’s predicted efficiencies versus more traditional factory models. It expects the concept to achieve:

- a 50 per cent reduction in the product development cycle;

- a 15 per cent increase in production efficiency;

- a 40 per cent reduction in product defect rate;

- a 30 per cent reduction in loss rate;

- a 5 per cent reduction in energy consumption;

- and the number of workers to be reduced by about 70 per cent compared with traditional factories.

ZC Rubber has been exploring the latest digital transformation strategies since 2016, when it introduced the ET Industrial Brain to create an Industry 4.0 Intelligent Manufacturing System. Now it wants to harness 5G technology to improve production capacity and efficiency, while also improving product quality and reducing production costs.

Comments