STARCO meeting robotic industry demand with puncture-free innovations

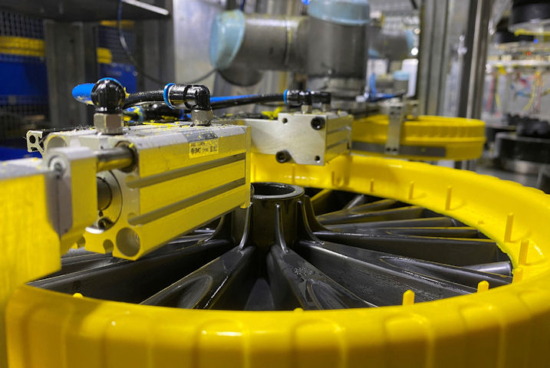

STARCO DML has implemented automated solutions & invested in robotic machinery to optimise manufacturing processes (Photo: STARCO)

STARCO DML has implemented automated solutions & invested in robotic machinery to optimise manufacturing processes (Photo: STARCO)

STARCO’s knowledge of light transportation applications, including tyre and wheel solutions for trolleys, sack trucks and wheelbarrows, has a long history. The firm is the largest Europe-based manufacturer of puncture-proof tyres in this segment, and it is drawing upon its experience and synergies in order to cater for a growing market.

Since STARCO – short for Scandinavian Tyre and Rim Company – was acquired by Kenda in 2017, a joint European R&D centre has complemented the Danish company’s strong engineering teams at its two manufacturing locations. Standard and bespoke steel wheels are produced in Croatia and innovative puncture-proof tyres in the UK. The team at STARCO DML in Crewe manufactures lightweight and high-quality wheel and tyre solutions for a variety of applications.

STARCO considers the 2006 launch of the Flex line, a revolutionary puncture-proof tyre assembly, to be a game-changer. On the back of this technology, one of its latest innovations, the Flex iCore2, combines the characteristics of the STARCO Flex Pro and STARCO Flex Lite in a tough and durable product that meets the requirements of professional users without compromising longevity or comparability with traditional pneumatics. STARCO has boosted manufacturing efficiency for these products by implementing automated solutions and investing in robotic machinery to optimise manufacturing processes.

The emerging puncture-proof tyre market is providing manufacturers the perfect ground to experiment. The development process and the success of the patented Flex Lite products have led STARCO’s design team to new directions. “We see the future of light transportation in high-technology wheel solutions. Home, garden, warehouse, transport and farming are growing markets for small robotic vehicles. One of our focus areas at the moment is urban transport,” comments Mike Andrews, managing director at STARCO DML.

New material combinations

Robotic vehicles place significant demands upon tyres. Superior performance, improved life expectancy and durability are crucial to success. Only an exceptional ride quality can protect the sensitive equipment within the robot.

“We are using a combination of materials in ways that haven’t been done before”, says Andrews. “Robots work consistently, therefore they need to run reliably. We combine different high-performance polymers to reach an optimum performance. We are designing one dynamic, homogenous component as opposed to separate ones. In other words, wheel and tyre are one piece. These new puncture-proof innovations will rely on end-of-life solutions that are five to six times more hard-wearing than conventional tyres.”

In addition, STARCO has committed to developing further scaled-up projects exploiting existing technologies combined with comprehensive research within new markets. “We are exploring new territories within heavier duty vehicles and industrial machinery like forklift trucks, smart robotic farm equipment and warehouse equipment”, reveals the STARCO DML managing director. “I strongly believe that relying on Kenda’s solid R&D experience, together we can achieve cutting-edge results.”

Comments