Bridgestone, Arlanxeo & Solvay present efficiency-increasing tyre technology

Nicolas Cudre-Mauroux (CTO Solvay), Herman Dikland (CTO Arlanxeo) & Emilio Tiberio (COO & CTO Bridgestone EMIA) introduced Techsyn

Nicolas Cudre-Mauroux (CTO Solvay), Herman Dikland (CTO Arlanxeo) & Emilio Tiberio (COO & CTO Bridgestone EMIA) introduced Techsyn

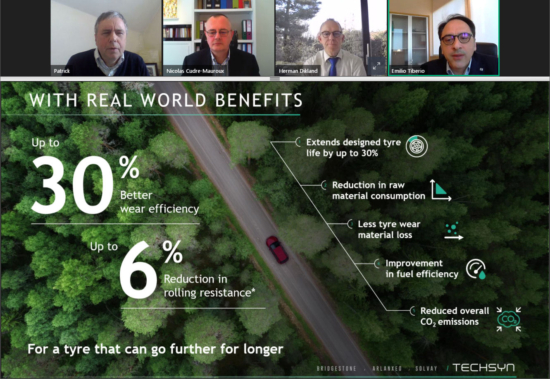

Improving a tyre’s wear efficiency by up to 30 per cent while decreasing rolling resistance by up to six per cent without affecting any other performance area sounds like a tall order. But Bridgestone says that it has achieved this together with partners Arlanxeo and Solvay. The three firms presented Techsyn, the fruit of two years of collaboration, during an online presentation this afternoon.

Bridgestone’s Emilio Tiberio says Techsyn offers “unrivalled strength and environmental performance” by utilising materials developed in parallel by the three companies. Specifically, it combines chemically optimised synthetic rubber with tailor-made silica, interacting at a molecular level, to “deliver outstanding performance with no trade-offs.”

No win/lose situation

The so-called ‘magic triangle’ of performance is a familiar concept within the tyre business, with changes to one of the key factors of wet traction and braking, rolling resistance and wear affecting the others. But according to Arlanxeo’s chief technology officer, Herman Dikland, Techsyn alters this triangle: “There is no win/lose situation.”

The partners explain that Techsyn possesses the “unique ability to balance a tyre’s performance across rolling resistance, wear and wet grip, and can be further adapted to meet varying needs.” For example, Techsyn’s wear advantage can be converted to instead enhance the tyre’s wet grip.

As Emilio Tiberio puts it, “we can tune into the best balance, depending on the customer’s needs.” A further example he gives of this is the flexibility that Techsyn offers by allowing tyre makers to decide between producing a tyre that uses less tread rubber than its predecessor while offering comparable mileage or a tyre with the same amount of tread rubber that can run for longer. “This is something that customers themselves can decide.”

Bridgestone primarily contributed to Techsyn by supplying technology related to compound design processes. Solvay brought its advanced silica materials to the table and Arlanxeo its expertise in developing, manufacturing and delivering tyre polymers. By working according to an aligned approach, the three companies were able to develop Techsyn more quickly than a consecutive approach would have allowed for. “Shaping a sustainable future of mobility, particularly when working at a rapid pace, isn’t an endeavour for just a single company,” comments Tiberio. “Collaboration is key.”

Flexibility to match any kind of product

The stated improvements in wear efficiency and rolling resistance are measured by comparing performance with that of Bridgestone’s conventional EMIA region summer products, and the tyre maker stresses that achieving these improvements doesn’t compromise performance in any other area.

Emilio Tiberio confirms that Techsyn “plugs into our Enliten package perfectly” and thus provides Bridgestone with additional options for expanding its Enliten portfolio. But this doesn’t mean Techsyn will be restricted to Enliten applications: “It has the flexibility to match any kind of product.”

Bridgestone is currently undertaking preparatory activities and tuning process prior to volume production of Techsyn-flavoured tyres. Tiberio won’t be drawn into sharing whether Bridgestone will prioritise one particular business line when rolling out Techsysn, commenting that the company will disclose its plans “in due time.”

Comments