Bridgestone reviews 2020 OE successes

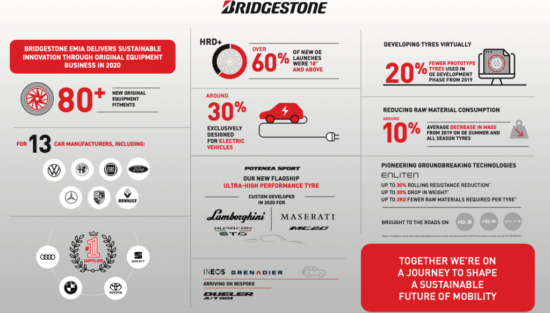

Over 80 fitments, more than 30 vehicle models, 13 car manufacturers – this is Bridgestone’s tally of new original equipment fitments for 2020. The tyre maker has summarised its OE achievements in an 80-second-long video. Steven De Bock, vice-president Consumer Replacement and OE at Bridgestone EMIA, comments that it’s “fantastic that we’ve been able to work in partnership with the world’s leading car manufacturers to meet our collective environmental goals and shape a more sustainable future of mobility.”

The year’s highlights include the arrival of Enliten technology, which first hit the road as an original equipment tyre for Volkswagen’s all-electric ID.3. Enliten technology reduces rolling resistance by up to 30 per cent compared with a premium Bridgestone summer tyre and reduces tyre weight by up to 20 per cent, which equals up to 2kg fewer raw materials used to produce the tyre. Enliten technology is now present in ten Bridgestone original equipment approvals, including on Volkswagen’s electric SUV the ID.4 and its new Golf 8.

Bridgestone points out that around 30 per cent of its original equipment fitments for the EIMA (Europe, Russia, Middle East, India and Africa) region last year were exclusively designed for electric vehicles. The tyre maker adds that from ologic Technology, created specifically for BMW’s all-electric i3, through to Enliten technology, it has “always supported the development of EVs through ground-breaking tyre technologies.”

Over 60 per cent of Bridgestone EMIA’s new original equipment launches in 2020 were within the HRD+ (18-inch and above) segment, reflecting growing consumer demand for larger tyre sizes.

Deploying technology to conserve raw materials

Bridgestone says Virtual Tyre Modelling represents the future of its tyre development, and the tyre maker is already using this today. The technology enables Bridgestone to create a digital twin of a tyre during its development, reducing the volume of physical prototype tyres and thus raw materials required during the process. This also cuts product development time by up to 50 per cent. Thanks to Bridgestone’s application of the technology in 2020, the company’s product teams produced 20 per cent fewer experimental tyres during the development phase when working on original equipment tyres for the EMIA region, compared with 2019. Furthermore, thanks again to the use of Virtual Tyre Modelling and the rise of indoor testing, Bridgestone EMIA reduced the distance travelled during fleet tests for original equipment tyres by 25 per cent year-on-year.

Technologies such as Enliten have also reduced the raw materials that go into each product. Original equipment summer and all-season tyres launched by Bridgestone EMIA to market in 2020 had an average mass approximately ten per cent lower than the same products from 2019.

Long-term & new partnerships

2020 was also the year that saw Bridgestone work with Lamborghini for the first time, as exclusive tyre supplier for its Huracán STO supercar. Bridgestone also developed bespoke Potenza Sport tyres for long-time partner Maserati’s MC20 supercar.

As well as working with historically revered brands, Bridgestone collaborated with a much-anticipated automotive newcomer in 2020: INEOS Automotive. The manufacturer’s permanent four-wheel drive Grenadier will arrive on the market with Bridgestone Dueler A/T 001 tyres as its standard fitment when it’s released in early 2022.

Looking through a sustainability lens

Commenting on Bridgestone EMIA’s OE achievements in 2020, Steven De Bock said: “2020 was about looking at all of our projects – from start to finish – through a sustainability lens first and foremost. By making conscious efforts to use fewer raw materials, develop and apply our virtual tyre development technology wherever possible, and install the sustainable tyre technologies we’re working on, like Enliten Technology, on more and more tyres, we’ve made great progress on this journey over the past 12 months.

“We’re pushing the boundaries of what is possible in engineering to deliver new cutting-edge products that are developed in more sustainable ways to offer an increasingly sustainable performance. It’s fantastic that we’ve been able to work in partnership with the world’s leading car manufacturers to meet our collective environmental goals and shape a more sustainable future of mobility.”

Geograph.co.uk

Geograph.co.uk

Comments