Michelin coordinates 16 million euro BlackCycle tyre circular economy project

Source: Michelin

Source: Michelin

Michelin is coordinating 7 industrial partners, 5 Research & Technological Organizations (RTOs) and an innovation cluster into a European consortium designing pioneering processes to produce new tyres from end-of-life tyres (ELTs). The project, called BlackCycle owing to its focus on developing a circular economy for tyres, is run across five countries.

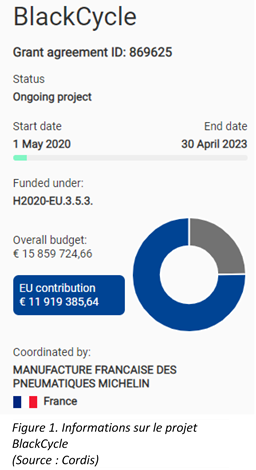

Officially funded by the EU in May 2020 (specifically by the European Union’s Horizon 2020 research and innovation programme under grant agreement No 869625), the BlackCycle par announced the launch of the project on 3 September 2020. The BlackCycle project involves 13 organisations in a European public-private partnership aims to demonstrate the technical, environmental, and economic viability of circular processes. Specific solutions investigated include: ELT collection and feedstock selection; pyrolysis optimisation, oil refining and valorisation; furnace process optimisation; and sustainable tyre performance assessment.

Source: Michelin

BlackCycle’s goals are lofty, with a launch document stating: “As early as 5-6 years after the project, close to 1 out of every 2 European ELTs will be incorporated into the only virtuous cycle of this magnitude amongst all industrial sectors for the recovery of end of life products.”

BlackCycle has an overall budget of about 16 million euros with allocated European funding of about 12 million euros (75% of project costs, see Fig. 1). About 35 per cent of the project funding is allocated to SMEs, 15 per cent to RTOs and 34 per cent corresponds to the personnel costs. The consortium runs across: France, Spain, Germany, Greece, and Switzerland. Coordinated by Michelin, the consortium has designed a governance system involving a steering committee, a cluster synergies board, and a technical support committee.

Ultimately, the BlackCycle project aims to create, develop and optimise a full value chain form ELT feedstock to Secondary Raw Materials (SRMs), with no waste of resources in any part of the chain and a specific attention for the environmental impact. These SRMs will be used to develop new ranges of passenger car and truck tyres, which will be sold commercially in European and global markets.

Nokian

Nokian

Comments