Conti releases new, ‘safer’ combine tyres

Continental’s CombineMaster tyre for combine harvesters includes a Hexa bead design to reduce tyre slippage, increasing safety and soil protection

Continental’s CombineMaster tyre for combine harvesters includes a Hexa bead design to reduce tyre slippage, increasing safety and soil protection

Continental CombineMaster designed with a Hexa bead to increase road safety and reduce soil compaction

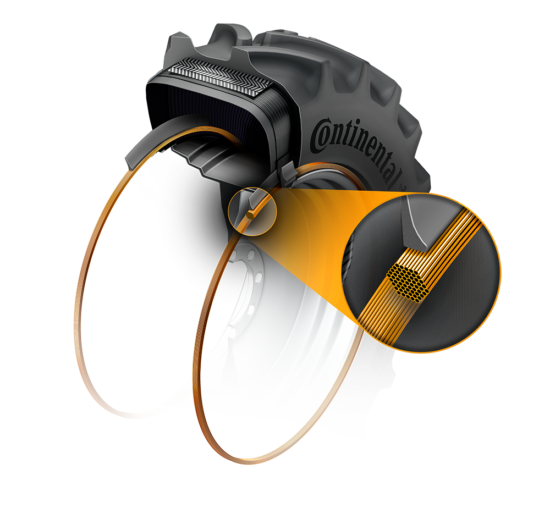

Continental has released a new combine harvester tyre, its first with a single filament bead core. In order to make the tyre safer and reduce slippage on the wheel, the manufacturer has designed a new bead construction for the the CombineMaster. In addition to road safety, reducing slippage also helps to reduce soil compaction – one of the most important considerations for agricultural tyre suppliers. By reducing compaction, the new tyre helps to protect the fissures in the soil that promote healthy growth. This increases the yield potential in the field. The tyre is the latest in Conti’s line of “Master” agricultural products. Conti has recently developed its agricultural tyre business with a 10-year guarantee and very high flexion (VF) fitment options.

Conti has achieved this in the CombineMaster with a unique Hexa bead construction. By using a bead core made of a single piece of steel wrapped around the circumference of the tyre up to one hundred times, Conti has created a combine tyre that holds its shape, even when run at very low pressures.

“Tyres with a single wire bead are safer and quicker to fit, hold the rim better and transfer torque more efficiently which reduces slippage,” explains Continental agricultural tyre specialist, Richard Hutchins.

Why the bead matters

The bead is an essential part of a tyre because it keeps the tyre on the rim of the wheel. Many agricultural tyres use as many as ten individual wires to create one bead. However, multiple joins in the bead can cause weaknesses and there is a risk that the tyre can detach from the rim, especially at low pressures.

“The bead is as important as the rubber and nylon in a tyre. Our research showed a more flexible tyre with a stronger single bead construction can be run at a lower pressure which helps to reduce soil compaction. Most importantly the tyre will grip the rim even at very low pressures. This reduces the risk of the tyre slipping off the rim whilst helping to spread the huge weight of a combine,” says Hutchins.

Conti adds that the hexagonal section of the bead is stronger and smoother than the common rectangular design which also makes it better on the road. “This is especially important for the front tyres which take more weight and torque. Our N.Flex carcass material coupled with the Hexa bead makes the CombineMaster tyre safer and more comfortable on the road,” says Hutchins.

Conti improves road usage

Continental’s patent pending N.Flex Technology is a heat-treated nylon that sits beneath the rubber to help the tyre return to its original shape following impacts and heavy use.

“Combine tyres reach high temperatures during road use. When parked overnight the tyres cool to the shape of the parked position creating so called flat spots. When the combine is used again the operator will experience ride disturbance because the tyres are not a perfect circle. N.Flex reduces the occurrence of flat spots and provides a more comfortable ride” explains Hutchins.

Jinyu

Jinyu Michelin/Ludovic Combe

Michelin/Ludovic Combe

Comments