‘Better than natural rubber’: Bridgestone creates new IR

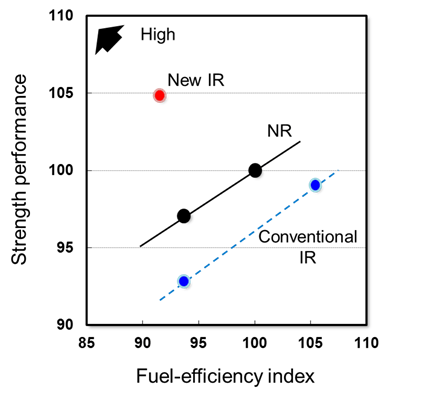

Performance of tyre materials created using the newly-synthesised IR

Performance of tyre materials created using the newly-synthesised IR

The promise is of not only a better-performing synthetic rubber, but also a sustainable one. Bridgestone Corporation has announced its successful creation of a new synthetic isoprene rubber (IR), something it achieved through precise molecular structure control utilising a new polymerisation catalyst. The company believes the new IR can deliver durability and fuel-efficiency performance surpassing that of natural rubber, and as it can be created using isoprene derived from renewable biomass, it offers the potential to be a sustainable material. Bridgestone aims to achieve the practical application of IR during the 2020s.

IR is usually manufactured using lithium (Li), titanium (Ti), or neodymium (Nd) catalysts. The gadolinium (Gd) catalyst Bridgestone developed is thus a completely new innovation. While it has been known that Gd catalysts have the potential to enable precise control of the molecular structure of IR, it was previously necessary for these catalysts to be used at temperatures below 0°C, which resulted in low activity and made manufacturing processes unfeasible. Bridgestone’s newly developed Gd catalyst, however, features a structure designed to enable it to be utilized to control IR molecular structure at temperatures above 40°C, the range commonly used in manufacturing processes. Moreover, the new Gd catalyst demonstrates activity of 1,800 cycle min-1, roughly 600 times higher than the activity of conventional Gd catalysts, making its use all the more practical.

Comments