Increased tyre changer automation ‘removes all worry of damage’

Paul Jarrold Tyres has been using two Hunter Revolution changers since mid-2015

Paul Jarrold Tyres has been using two Hunter Revolution changers since mid-2015

A Monmouth tyre dealer has spoken of the benefits offered by the Hunter Revolution tyre changer’s almost fully automated procedures. Pro-Align, Hunter’s distributor, demonstrated the machine to Tyres & Accessories when it first arrived in the UK, and now the changer is proving its value in the real world at garages like Paul Jarrold Tyres. Technician Matt Robert-Buxton said: “As an operator it removes all worry of damage to tyres, rims and TPMS, resulting in stress-free tyre changing.” The retailer has been running two Revolution changers since June 2015.

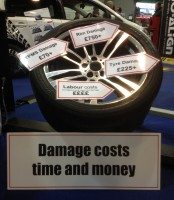

Pro-Align states that workshops can save thousands of pounds in damage repair costs and increase their efficiency with the Hunter Revolution. Based on premium tyre and wheel fitments, the machine’s distributor estimates that damage caused when changing a tyre can exceed £1,000 (based on replacement rims of more than £750, tyre costs of more than £225 and replacement TPMS costs of more than £70). While this is at the top end of these costs, damage to any of these components can certainly hit retailers’ margins at a time when revenues from additional servicing has never been more important.

Pro-Align believes the tyre changer is “the most advanced changer available in the aftermarket today.” In addition to damage prevention, T&A has seen how the Revolution can help technicians to change tyres sized up to 50” in diameter in the same way, taking the same amount of time, regardless of tyre size or type. This makes it highly efficient.

Pro-Align estimates damage costs from a botched tyre change can top £1,000

“In a busy workshop, it’s all too easy for technicians to inadvertently cause damage to tyres, rims or TPMS sensors when changing tyres,” explains Paul Beaurain, managing director, Pro-Align. “These costs can soon mount up, and are likely be particularly significant when working on luxury or prestige vehicles which are equipped with expensive alloy rims or ultra-low-profile or high performance tyres. Thankfully, Revolution can eradicate any such costs and problems as well as help to enhance a professional, quality reputation.”

With an integrated spindle wheel lift and swift central clamping, the technician is soon setting the diameter and position of the valve or TPMS unit. Depressing the machine’s foot pedal initiates all functions, including breaking the beads, and using its leverless hook to demount the bead. TPMS systems are even tracked automatically.

Once the technician replaces the tyre, the Revolution’s power arm mounts this onto the rim. After the hose is connected to the tyre, it inflates safely to its correct operating pressure. As with many Hunter systems, animations and help videos are available through the system interface, to help any technicians who require additional assistance or explanation.

Comments