Hunter Revolution ‘eradicates’ TPMS sensor damage – Pro-Align

The Hunter Revolution automates tyre changing, helping operators to protect tyres and TPMS sensors

The Hunter Revolution automates tyre changing, helping operators to protect tyres and TPMS sensors

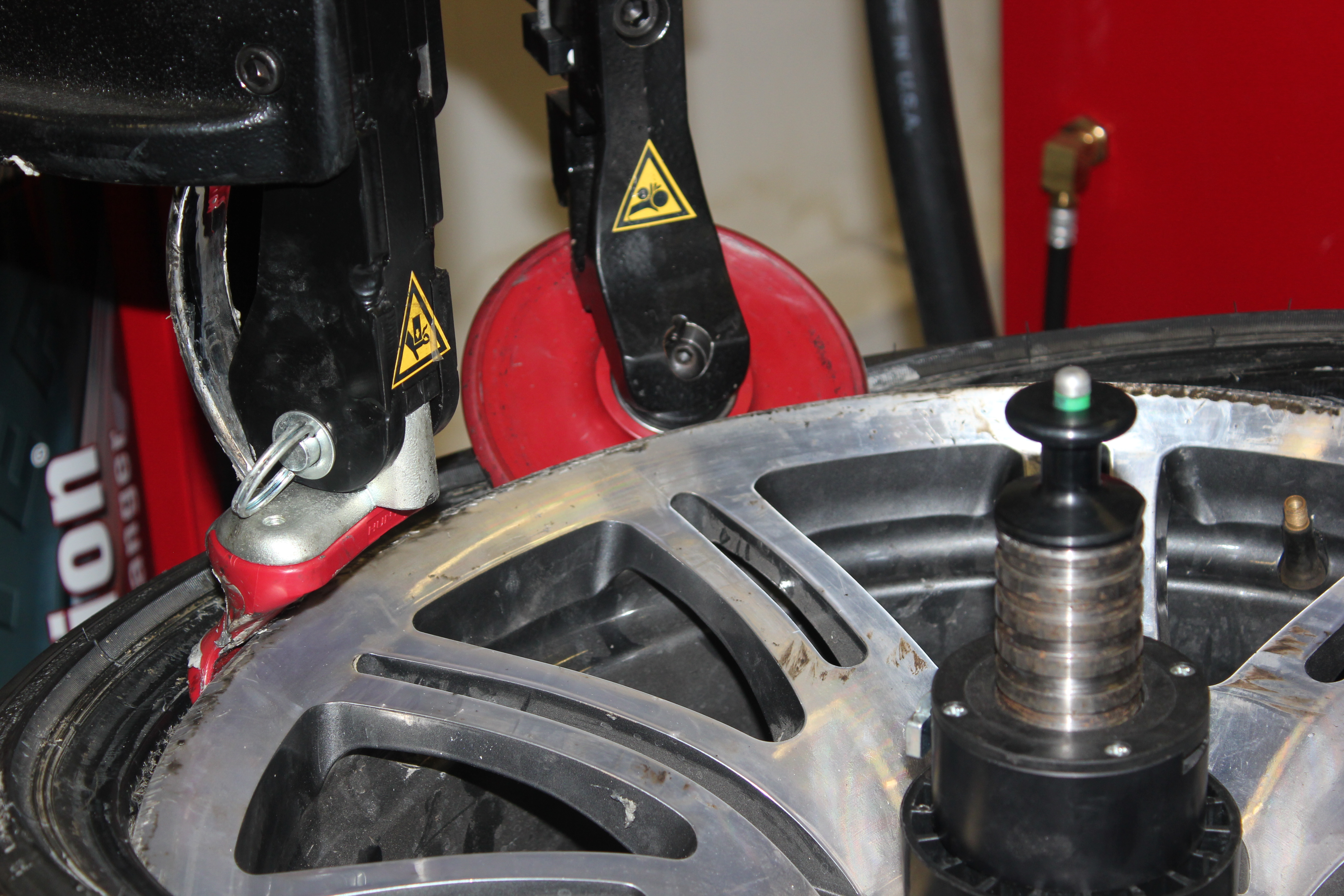

Damage to tyre pressure monitoring system sensors caused during the tyre removal and refit process can be an expensive problem, but a UK garage equipment supplier believes the Hunter Revolution can prevent this unfortunate side effect from occurring. Pro-Align launched the new (almost) fully automated tyre changer from Hunter last year – Tyres & Accessories was able to preview the machine as it went on sale – and the system’s process actively works to prevent sensor damage. The Revolution also allows tyres to be changed effortlessly in exactly the same way every time, requiring the same amount of time regardless of tyre size or type. As well as helping workshops avoid damage to customers’ TPMS sensors, the machine can also improve workshop efficiency and effectiveness, Pro-Align adds.

“By law, all new cars are now equipped with TPMS and they must be properly functioning for the car to pass its MOT,” explains Paul Beaurain, managing director, Pro-Align, the exclusive UK distributor of Hunter wheel servicing systems. “It’s therefore important that workshops are properly equipped to be able to change tyres without causing damage to these sensitive and expensive units. Often, damage can occur quite easily through incorrect positioning of levers or simply because technicians are rushing to complete the task and move onto the next waiting job. With the fully automated Revolution tyre changer, is simply isn’t possible to cause this damage.”

To operate the Revolution, technicians use an intelligent foot pedal and touch screen interface. All functions of changing the tyre such as breaking the bead and using the leverless hook to demount the bead are controlled without any hands-on assistance from the user. In order to protect the TPMS sensor attached to the wheel rim, the Revolution asks users to identify the valve position and its intelligent operation ‘knows’ that location to ensure that potentially damaging pressure is never applied to that area of the rim or tyre.

With its fully automated process, the Revolution also provides workshops with greater flexibility. No longer is it necessary for specific staff who have been trained on working with TPMS to carry out the work as the changer can be easily operated by all technicians.

“With replacement TPMS sensors sometimes running into a cost of more than a hundred pounds, along with the time needed to replace and recode them, workshops can’t afford to damage them. The Revolution is an ideal way to ensure this doesn’t happen,” concludes Beaurain.

Comments