Hofmann Megaplan launches apprenticeship scheme

Hofmann Megaplan business analyst and special projects manager, Andy Hawes presents the company to students at Huntingdonshire Regional College

Hofmann Megaplan business analyst and special projects manager, Andy Hawes presents the company to students at Huntingdonshire Regional College

Cambridgeshire garage machinery firm Hofmann Megaplan has launched an apprenticeship scheme. The provider of wheel aligners, lifts and a broad range of other equipment and tools said that the initiative represented a longer term approach in training up inexperienced individuals receptive to Hofmann Megaplan’s “way of doing business.” The company added that “finding new recruits who can demonstrate the passion and commitment to our brand and philosophy has proven difficult, as those coming from competitors or other sectors within garage equipment often have their own set ways and opinions.”

In order to find candidates for apprenticeships, Hofmann Megaplan has built a partnership with its local technical college to source a number of students each year. The company said it would teach students the ropes in “a buoyant and consistent trade, with the opportunity to pursue a very rewarding career working for a solid, reputable company with a reputation for valuing their employees.”

The company’s business analyst and special projects manager, Andy Hawes said: “Hofmann Megaplan has grown into a significant business within the garage equipment industry. Yet there is still the overwhelming feeling of a family business, and the team spirit is admirable and essential to the success we continue to enjoy. The goal is now to find new people out there who can help maintain that atmosphere whilst helping the company progress and expand in line with the ever-increasing level of business”.

Alignment and lifts range

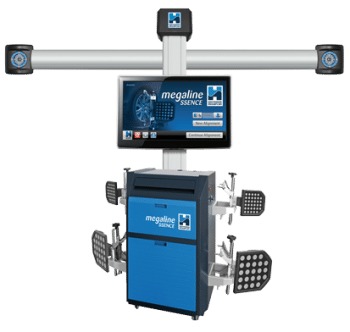

Hofmann Megaplan’s Megaline Ssence 3D wheel aligner is available in two versions

Hofmann Megaplan’s current range of wheel alignment machinery is led by the Megaline Ssence 400 and 600. These 3D wheel aligners contain the latest alignment technology, the company states; utilising the reflective target measuring head and camera system, the Ssence is built to be both fast and simple to use, making it a good choice for customers looking to invest in operator-friendly technology with improved throughput. It is the most advanced wheel aligner available from Hofmann Megaplan, with software designed to make life as easy for the operator as possible, minimising unnecessary procedures commonly found on other, similar systems.

Garages can choose between the more economically-priced 400, or the more advanced 600, with a 32” display and automatic camera boom.

The Ecoline 58 represents what Hofmann Megaplan calls the logical next step up for anybody wanting to move on from a laser system to a fully computerised aligner.

As the distributor states, its computerised alignment enables operators to charge a premium for alignment services, since businesses are able to provide the customer with a printout showing the starting alignment and the results of their purchased service. Hofmann Megaplan claims that the Ecoline 58 will yield “the same results as competitors’ systems that are literally five times the price.” It provides the benefit of a built-in vehicle database, live readings and technical prompts, and a customer printout, without the heavy investment required in other machines.

The more compact Ecoline 58 takes advantage of infra-red and wireless technology. The Hofmann Megaplan offers the machine for “£25 plus VAT per week”, and estimates that the machine can earn garages “hundreds of pounds a day.”

Hofmann Megaplan also offers an upgraded version of the 58. The Ecoline 88 is based on the same platform as the 58, but includes some luxury additional features such as three-point ‘GrabClamps’, heavy duty mechanical turnplates and advanced measuring heads, making full four wheel alignment easier and faster.

The ‘GrabClamps’ mean that the measuring head is mounted to the wheel using sprung-loaded arms that grab the tyre, and three nylon locators on the rim, ensuring there is no metal to metal contact.

Hofmann Megaplan is also the exclusive distributor of Cascos branded lifts. The Spanish brand is celebrating 50 years since its foundation by former Volkswagen and Mercedes employee, Carlos Alvarez-Cascos Snr. Having used his contacts and knowledge gained working at the German Volkswagen factory and the Spanish Mercedes-Benz factory to sell a range of in-ground lifts for trucks in 1965, the company opened its first 1500m2 of office and production facilities to develop the first series of two-post lifts and tyre changers, predominantly destined for the German market.

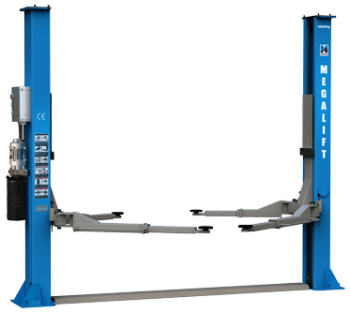

Hofmann Megaplan’s two-post Megalift 3000

Hofmann Megaplan said Cascos’ partnership and experience with the German market led to its affinity for build quality and design associated with German-made lifts. The distributor now sells a full range of Cascos lifts, including four-post, two-post, and one-post lifts, a scissor lift and a motorcycle lift.

Hofmann Megaplan also supplies a self-branded basic two-post vehicle lift, the Megalift 3000. The electro-hydraulic lift combines an economic design typical of entry-level lifts with Hofmann Megaplan’s associated qualities, which it characterises as build-quality, reliability, long-term spares availability and reputation.

The lift is designed and CE-certified as a 4000kg capacity lift, though Hofmann Megaplan decided to market it as a 3000kg capacity, to allow it to comply with EU legislation not required from non-EU manufactured lifts.

Comments