Marangoni invests in super-wide singles – “the future of road transport”

Marangoni has invested in super wide single production capacity in Ferentino

Marangoni has invested in super wide single production capacity in Ferentino

The super wide segment, which refers to tyres with a tread width exceeding 325mm, has been grown exponentially all over the world in recent years. These tyres have been used in Europe as trailer tyres for many years, however more recently they have also gained favour in North America and their applications have progressively extended to cover drive and front axle fitments.

Super wide single tyres are used in place of twin wheels, bringing evident benefits and sure savings for fleets: considerable fuel savings (up to six per cent), a wider tread footprint and better stability, extra load due to the reduction in overall vehicle weight, no need to rotate tyre position on the vehicles, easier maintenance and lower purchase costs – benefits gained through the need to only buy just one tyre rather than two. “The fuel savings gained through low rolling resistance super wide tyres mean these products come with the highest labelling classification in terms of fuel consumption, as certified by the SmartWay programme,” comments Marangoni Retreading Systems in a statement.

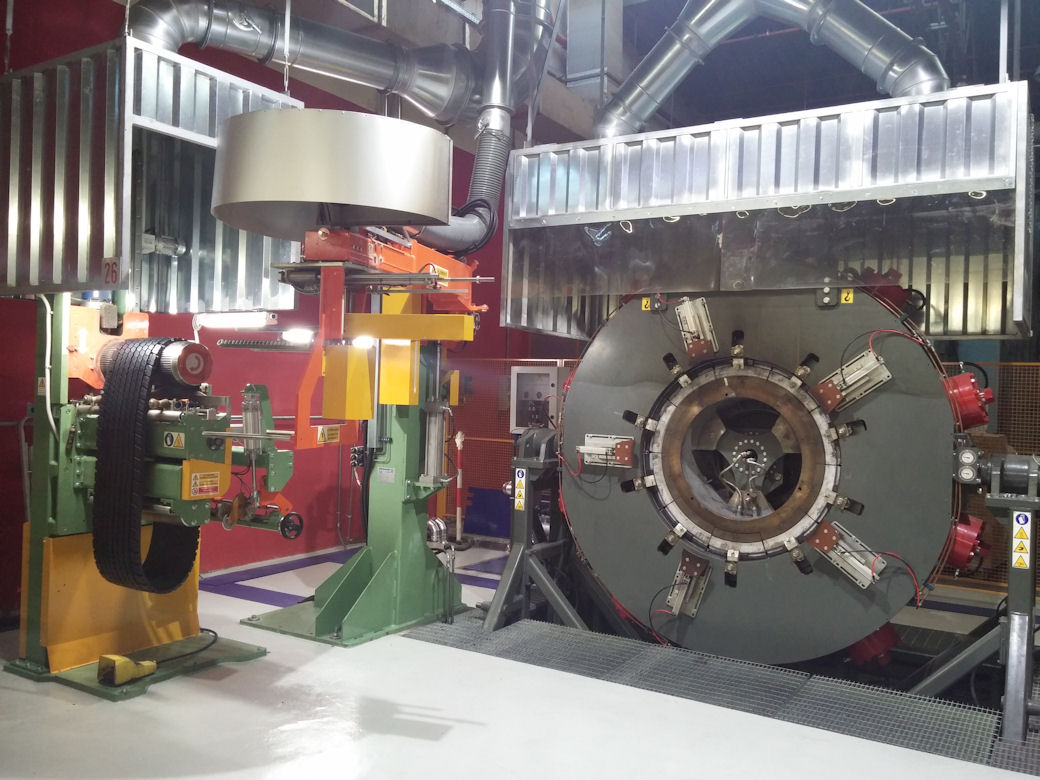

“The dimensions of these tyres make retreading with the Ringtread system especially advantageous, due to the circular shape and the absence of the usual joint and lack of uniformity in distribution of the material applied, typical of traditional pre-cured strips,” continues Marangoni, adding that it intends to more strongly focus on market trends associated with super wide singles. It says it aims to “anticipate and meet the increasingly demanding needs of fleets” and has decided to take on a new challenge: the design and development of new tread patterns, new purpose-designed compounds, and a special press for the production of tread rings up to 450 mm wide.

“This machine stands out for the very high specific moulding pressure, thus ensuring the renowned benefits of the Ringtread. The press can be fed both in the traditional manner, with extruded sections of rubber, or using one or two extruders to make the process completely automatic,” reports Marangoni Retreading Systems. The new press has been installed at the company’s production plant in Ferentino, Italy, and is the second such press in the facility. Its entry into service and ability to retread up to 150 super wide single Ringtreads a day has doubled production capacity in Ferentino for a product Marangoni Systems calls the “future of road transport.”

Comments